Ammonium Sulfate Market Report Scope & Overview:

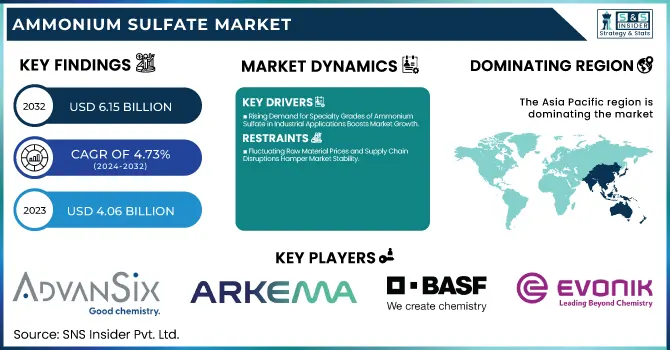

The Ammonium Sulfate Market Size was valued at USD 4.06 Billion in 2023 and is expected to reach USD 6.15 Billion by 2032, growing at a CAGR of 4.73% over the forecast period of 2024-2032.

To Get more information on Ammonium Sulfate Markett - Request Free Sample Report

The Ammonium Sulfate Market is driven by its widespread use in fertilizers, water treatment, and industrial applications. Our report explores the cost structure, analyzing raw material, energy, and labor expenses shaping production economics. Strategic investment and ROI analysis highlight capital requirements and profitability trends. Regulatory compliance is crucial, with international quality and safety standards like REACH and EPA regulations impacting trade. Understanding consumer perception and buying behavior reveals shifting demand in agriculture and industry. Additionally, competition from substitutes challenges market growth, making adoption rates of alternative products a key factor. Our research provides exclusive insights into these elements, offering a comprehensive view of the ammonium sulfate industry’s evolving landscape.

Ammonium Sulfate Market Dynamics

Drivers

-

Rising Demand for Specialty Grades of Ammonium Sulfate in Industrial Applications Boosts Market Growth

Ammonium sulfate is no longer confined to its traditional role in agriculture; it is increasingly gaining prominence in industrial applications, including pharmaceuticals, food additives, and water treatment. The growing demand for high-purity ammonium sulfate grades in these sectors is creating new growth opportunities for manufacturers. In the pharmaceutical industry, ammonium sulfate is widely used as a stabilizing agent in drug formulations and vaccine production, driving demand for ultrapure variants. Similarly, in the food industry, ammonium sulfate serves as a dough conditioner and food preservative, requiring compliance with stringent safety standards. Another significant application is in wastewater treatment, where ammonium sulfate acts as a coagulation agent, aiding in the removal of impurities from industrial effluents. With increasing environmental regulations mandating effective water purification solutions, the role of ammonium sulfate in industrial water treatment is expanding. Manufacturers are now investing in advanced purification techniques to cater to industries with strict quality requirements, further fueling market growth. As industries seek reliable and high-performance chemical solutions, ammonium sulfate’s diverse industrial applications are set to drive sustained market expansion.

Restraints

-

Fluctuating Raw Material Prices and Supply Chain Disruptions Hamper Market Stability

The ammonium sulfate market is highly dependent on the stability of raw material supply and production costs, making it vulnerable to price fluctuations and supply chain disruptions. Since ammonium sulfate is primarily produced as a byproduct of caprolactam manufacturing, any variations in the demand or supply of caprolactam directly impact ammonium sulfate availability. Additionally, raw materials such as ammonia and sulfuric acid experience frequent price volatility due to changing global demand, geopolitical tensions, and disruptions in the chemical industry. Supply chain inefficiencies, such as transportation constraints and trade restrictions, further exacerbate the challenge of maintaining a steady ammonium sulfate supply. The COVID-19 pandemic and other economic disruptions have highlighted vulnerabilities in the global supply chain, leading to unpredictable market conditions. These uncertainties make it difficult for manufacturers to maintain consistent pricing strategies, affecting profit margins. To address these challenges, companies are exploring alternative production methods and securing long-term supply contracts, but the inherent volatility in raw material prices remains a significant restraint for the ammonium sulfate market.

Opportunities

-

Emerging Applications of Ammonium Sulfate in Battery Technologies Drive Future Market Growth

As the demand for advanced energy storage solutions rises, researchers are exploring new applications of ammonium sulfate in battery technologies. Recent studies indicate that ammonium sulfate can enhance electrolyte stability in lithium-sulfur and flow battery systems, improving battery efficiency and lifespan. With the global push toward renewable energy and electric vehicles, the need for cost-effective and high-performance battery materials is growing rapidly. Companies involved in battery research and development are testing ammonium sulfate as a potential component in next-generation energy storage solutions. Collaborations between chemical manufacturers and battery technology firms are expected to accelerate innovation in this space. The shift toward alternative battery chemistries that reduce reliance on scarce or expensive materials is also driving interest in ammonium sulfate-based solutions. If successfully integrated into commercial battery systems, this application could open new revenue streams for ammonium sulfate manufacturers. As the energy storage market expands, ammonium sulfate’s role in battery technologies presents a promising opportunity for future market growth.

Challenge

-

Limited Awareness and Adoption of Specialty Ammonium Sulfate Grades in Emerging Markets

Despite the increasing demand for high-purity ammonium sulfate, many developing regions still rely on conventional fertilizers and basic industrial chemicals. Awareness of specialty ammonium sulfate grades remains low among small-scale farmers and industrial users, limiting adoption. Additionally, inadequate infrastructure for specialty chemical distribution makes it challenging to supply advanced ammonium sulfate formulations to emerging markets. The high cost of specialty grades also deters price-sensitive consumers, reducing their accessibility. Companies must invest in educational initiatives, training programs, and marketing campaigns to increase awareness of specialty ammonium sulfate benefits. Strategic partnerships with local distributors and agricultural cooperatives can help improve market penetration. Overcoming these barriers will require long-term efforts to enhance product visibility, accessibility, and affordability in emerging economies.

Ammonium Sulfate Market Segmental Analysis

By Form

Solid ammonium sulfate dominated the ammonium sulfate market in 2023 with a 78.5% market share. The dominance of solid ammonium sulfate is driven by its cost-effectiveness, ease of handling, and long shelf life compared to liquid alternatives. Solid ammonium sulfate is widely used in agriculture as a nitrogen and sulfur fertilizer, particularly in large-scale farming across Asia-Pacific, Europe, and North America. According to the International Fertilizer Association (IFA), global nitrogen fertilizer demand increased in 2023, with ammonium sulfate being a key component in crop nutrition. The U.S. Department of Agriculture (USDA) has also promoted the use of ammonium sulfate in precision farming, further driving its demand. Additionally, major fertilizer producers such as Nutrien and Gujarat State Fertilizers & Chemicals Limited have expanded their production of solid ammonium sulfate to meet rising agricultural needs, reinforcing its dominant position in the market.

By Production Process

The caprolactam byproduct process dominated the ammonium sulfate market in 2023 with a 62% market share. This method remains the most widely used due to its cost-efficiency and sustainability, as it utilizes ammonium sulfate as a byproduct of caprolactam production, reducing industrial waste. Major manufacturers such as BASF, Fibrant, and Sumitomo Chemical rely on this process to produce ammonium sulfate, ensuring consistent supply and cost-effectiveness. According to the European Chemical Industry Council (CEFIC), caprolactam production has expanded in key markets such as China, Europe, and North America, further supporting the dominance of this production method. Additionally, environmental regulations promoting circular economy practices, such as the European Union’s Green Deal, have encouraged companies to maximize the utilization of industrial byproducts, reinforcing the widespread adoption of this process in the ammonium sulfate market.

By Application

Fertilizers dominated the ammonium sulfate market in 2023 with a 75.4% market share. The agricultural sector heavily relies on ammonium sulfate as a nitrogen and sulfur-based fertilizer to enhance soil fertility and crop yields. According to the Food and Agriculture Organization (FAO), the demand for fertilizers grew steadily in 2023, particularly in countries like China, India, and Brazil, where ammonium sulfate is widely used in rice, corn, and wheat cultivation. Governments worldwide, including China’s Ministry of Agriculture and Rural Affairs, have implemented subsidies and soil improvement programs that encourage farmers to adopt ammonium sulfate-based fertilizers. Additionally, companies such as Nutrien and OCI Global have increased their production capacity to cater to the growing demand from the agricultural sector. With rising global food production needs and the importance of soil nutrient management, ammonium sulfate continues to be the preferred fertilizer choice, solidifying its dominant position in the market.

Ammonium Sulfate Market Regional Outlook

Asia Pacific dominated the ammonium sulfate market in 2023 with an estimated market share of 42.7%. The region's dominance is primarily driven by the high consumption of ammonium sulfate in the agricultural sector, especially in countries like China, India, and Indonesia, where large-scale farming requires nitrogen and sulfur fertilizers to enhance crop yields. According to the Food and Agriculture Organization (FAO), China alone accounted for nearly 30% of global fertilizer consumption in 2023, with ammonium sulfate playing a key role in rice and wheat cultivation. India, supported by government initiatives such as the Pradhan Mantri Kisan Samman Nidhi (PM-KISAN) and fertilizer subsidies, has witnessed significant demand for ammonium sulfate-based fertilizers. Indonesia, a major palm oil producer, also relies on ammonium sulfate for improving oil palm yield. Additionally, major manufacturers such as OCI Global and SINOPEC CORP. have expanded their production facilities in the region to meet the growing demand. The presence of cost-effective production methods, abundant raw material availability, and favorable government policies further solidify Asia Pacific’s leading position in the ammonium sulfate market.

On the other hand, Europe emerged as the fastest-growing region in the ammonium sulfate market, with a significant growth rate during the forecast period. The region’s rapid growth is attributed to increasing adoption of ammonium sulfate for sustainable farming practices and strict environmental regulations that promote its use as an eco-friendly fertilizer. The European Union’s Common Agricultural Policy (CAP) has encouraged farmers to utilize ammonium sulfate to enhance soil fertility while reducing nitrogen losses. Germany, the largest agricultural producer in Europe, has witnessed a rising preference for ammonium sulfate due to government-backed incentives for sulfur-based fertilizers. France, another key market, has seen an upsurge in ammonium sulfate demand for vineyards and wheat farming, supported by subsidies under the EU Green Deal. The Netherlands, a major hub for chemical industries, has also increased ammonium sulfate production through companies such as BASF and DSM. With growing demand for sustainable fertilizers and government regulations favoring ammonium sulfate usage, Europe is poised to experience significant market growth.

Get Customized Report as per Your Business Requirement - Enquiry Now

Key Players

-

AdvanSix

-

BASF SE

-

DOMO Chemicals

-

Evonik Industries AG

-

Fibrant

-

Gujarat State Fertilizers & Chemicals Limited

-

Helm AG

-

LANXESS

-

Merck KGaA

-

Nutrien

-

OCI Global

-

OSTCHEM

-

SINOPEC CORP.

-

Sumitomo Chemical Co., Ltd.

-

UBE Corporation

-

Vinipul Inorganics Pvt. Ltd.

-

ArcelorMittal SA

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 4.06 Billion |

| Market Size by 2032 | USD 6.15 Billion |

| CAGR | CAGR of 4.73% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | •By Form (Solid, Liquid) •By Production Process (Caprolactam Byproduct Process, Coke Oven Gas Process, Gypsum Conversion Process, Neutralization Process) •By Application (Fertilizers, Pharmaceuticals, Food & Feed Additive, Water Treatment, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | BASF SE, Evonik Industries AG, Sumitomo Chemical Co., Ltd., LANXESS, Domo Chemicals, Arkema, OCI Global, Fibrant, AdvanSix, Nutrien and other key players |