High Pressure Seals Market Report Scope & Overview:

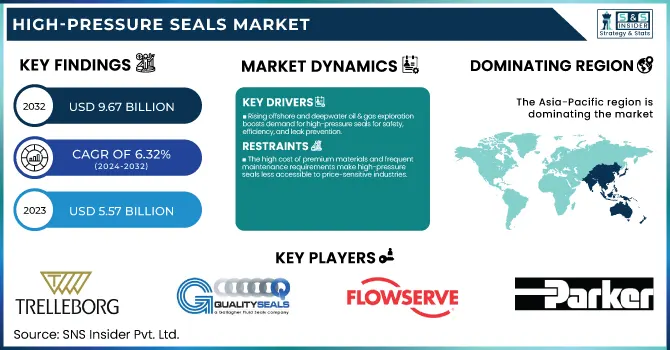

The High Pressure Seals Market Size was estimated at USD 5.57 billion in 2023 and is expected to arrive at USD 9.67 billion by 2032 with a growing CAGR of 6.32% over the forecast period 2024-2032. The High-Pressure Seals Market report provides a unique analysis of material utilization trends (Elastomers, Metals, and Composites), highlighting the growing preference for composite-based seals due to their durability in extreme conditions. It explores innovation adoption by region, with technologically advanced sealing solutions gaining traction in key markets. The study examines manufacturing capacity and production output, showcasing expansions by major players to meet increasing demand. Additionally, it covers supply chain dynamics, including raw material shortages and distribution challenges, along with import/export trade shifts, emphasizing regional export growth. To enhance uniqueness, the report also delves into sustainability trends, focusing on the rising adoption of bio-based and recyclable high-pressure seals.

To Get more information on High-Pressure Seals Market - Request Free Sample Report

High Pressure Seals Market Dynamics

Drivers

-

The growing oil & gas exploration activities, especially in offshore and deepwater fields, are driving the demand for high-pressure seals to ensure safety, efficiency, and leak prevention.

The High-Pressure Seals Market is witnessing significant growth, driven by increasing demand from the oil & gas industry. In past years, growth in oil and gas energy demands has triggered further offshore and, onshore exploration activities across the world, particularly in North America, the Middle East, and Asia-Pacific. Conclusion High-Pressure Seals are the most essential components to safeguard, leak resistance, and maintain any pressure critically equipment like valves, pumps, and drilling. This consistency is being achieved by using advanced multispectral material technology, which focuses on increasing the durability and reliability of seals under extreme conditions like PTFE, elastomers, metal seals, etc., during high-pressure and high-temperature profiles. The movement in the industry toward subsea and deepwater exploration also leads to a greater need for high-performance seals. Investments across the hydrogen production chain, LNG infrastructure, and petrochemical facilities with a requirement for high-performance seals are also indicated by market trends. Demand for eco-friendly self-lubricating seals in line with sustainability targets is also increasing.

Restraint

-

The high cost of premium materials and frequent maintenance requirements make high-pressure seals less accessible to price-sensitive industries.

The high initial costs and maintenance requirements of high-pressure seals pose a significant challenge for industries that rely on cost-effective solutions. Owing to their ability to withstand excessive pressures, temperatures, and reactive environments, they are usually designed using high-performance materials like PTFE, advanced elastomers, and unique metals. Yet because they are high-performance and individually engineered to tight tolerances, production costs are prohibitive, pushing these drives outside the limits of economies to care about price (small-scale manufacturing, scatter-gun industrial applications, etc.) To keep them running smoothly, they do require periodic maintenance to prevent wear and tear, which under extreme operating conditions may result in leakage, system failure, and costly downtime. Those sectors that are heavy users of these MVPs and reliability (oil & gas, aerospace, chemical processing, etc.) may swallow the cost, but other sectors may be seeking lower-cost solutions. The impediment of the high price point discourages mass adoption, compelling manufacturers to innovate low-cost and durable sealing solutions.

Opportunities

-

Advancements in seal materials, including composite seals, nanotechnology coatings, and self-lubricating designs, enhance durability, performance, and efficiency in extreme conditions.

Technological advancements in seal materials are revolutionizing the high-pressure seal market by enhancing durability, performance, and efficiency. Composite seals, made from a combination of multiple materials from PTFE (Polytetrafluoroethylene) to elastomers to metals also add to their extreme temperature as well as pressure and chemical excretion resistance. They work using nanotechnology to reduce friction and wear, increasing seals' lifespan and maintenance of seals under extreme conditions. State-of-the-art, self-lubricating seals also utilize specialty polymers or solid lubricants, which reduce reliance on external lubrication, enabling smoother, long-lasting operation with longer service intervals. This is specifically applicable to sectors such as oil & gas, aerospace, and power generation where extreme operating conditions require high-performance sealing solutions. Additionally, developments in bio-based and sustainable materials will further drive the need for green products, to adhere to global environmental regulations.

Challenges

-

Economic slowdowns reduce demand for high-pressure seals as key industries cut expenditures, delay projects, and scale down operations.

Economic slowdowns can significantly impact the high-pressure seals market by reducing demand from key end-use industries such as automotive, oil & gas, and power generation. Economic downturns often lead companies in these industries to reduce capital expenditures, postpone new projects, and work to optimize operating costs all of which contribute to reduced demand for high-pressure seals. The oil & gas industry, the largest consumer of these seals, is at high risk as the price of crude oil in global markets can cause a decline in drilling and refining activities. The car industry, which produces and sells a broad range of vehicles lower during periods of economic recession leading to reduced demand for high-performance sealing materials. In the power sector, also, market growth might also be hindered by delays in infrastructure investments and renewable energy projects. In addition, supply chain disruptions, inflationary pressures, and falling industrial output pose further challenges, making it difficult for manufacturers of seals to maintain profitability and grow their market presence during periods of economic contraction.

High Pressure Seals Market Segmentation Analysis

By Application

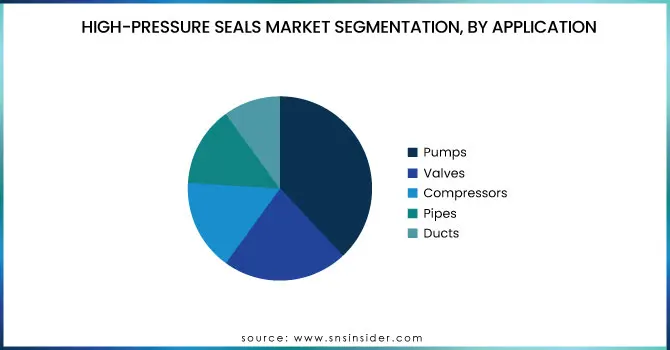

The Pumps segment dominated with a market share of over 38% in 2023, primarily due to its widespread application across industries such as oil & gas, chemical, and power generation. Operating in high-pressure environments, these industries require durable and efficient sealing solutions to prevent leakage and enable safe operations. Maintaining high-pressure seals in pumps prolongs equipment life while reducing downtime and increasing overall efficiency, making them crucial for critical applications. High-pressure seals are being increasingly adopted in pumps due to the increasing demand for energy, growing industrialization, and advancements in sealing technologies. As the demand for fluids transported under high-pressure environments increasingly grows, the market subject-wise is dominated by the pumps segment, where technological advancements and strict safety compliance in industrial operations act as a driving factor.

By Material

The Elastomers segment dominated with a market share of over 32% in 2023, the High-Pressure Seals Market due to their exceptional flexibility, durability, and sealing efficiency under extreme conditions. Withstand high pressures and temperatures, these hard-facing alloys are suitable for demanding applications in sectors such as oil & gas, chemical processing, power generation, and aerospace. They have excellent chemical, wear, and deformation resistance, making them relatively good long-term solutions for harsh environments. Furthermore, the development of improved elastomer compounds has also helped increase their thermal stability and pressure rating, contributing to their increased use. Market leadership to their increasing demand for reliable sealing measures like high-performance machinery and equipment. Moreover, rapid industrialization and the growth of energy sectors across the world persist in driving the demand for elastomer-based high-pressure seals.

By End Use

The power generation segment dominated with a market share of over 34% in 2023, due to the critical role of these seals in turbines, heat exchangers, boilers, and reactors. For power plants, including thermal, nuclear, and renewable energy plants, high-pressure seals play an important role in preventing leaks and optimizing performance and safety. The importance of durable and high-performance sealing solutions is growing with the global energy demand and significant investments in power infrastructure. Also, the transition to wind and hydroelectric power has increased the need for high-performance sealing technologies. The modernization of old power plants and new facilities, which are built globally, also leads this segment to dominate the market.

High Pressure Seals Market Regional Outlook

Asia-Pacific region dominated with a market share of over 42% in 2023, driven by rapid industrialization and increasing investments in oil & gas, chemical processing, power generation, and manufacturing sectors. Power generation, and manufacturing sectors. Led by countries such as China, India, and Japan, infrastructure development and large-scale energy projects are driving the need for high-performance sealing technologies. Major manufacturing facilities, increasing usage of high-tech industrial machines, and growing demand for seals in high-pressure applications in the region further consolidate this region's dominance. Also, market growth is facilitated by the growing government initiatives for the promotion of industrial expansion and energy efficiency. The continued increase in the production of vehicles, aircraft, and heavy machinery is deemed to play a crucial role and is likely to strengthen the Asia Pacific high-pressure seals market share as a leading region.

North America is the fastest-growing market for high-pressure seals, driven by advancements in oil & gas exploration, aerospace, and pharmaceutical industries. This has led to an increase in demand across industries with the growing demand for high-performance sealing solutions in extreme pressure and temperature situations. In addition, increasing investments in industrial automation and energy-efficient technologies are propelling the market growth. This is largely attributable to the U.S. and Canadian growth factors, the strong influence of technology, the rapid expansion of safety regulations, and more industries adopting advanced manufacturing processes. Increased demand in the region is also driven by the strong emphasis on improving operational efficiency and minimizing leakage risks in high-pressure applications. Currently, North America is the biggest producer and highest consumer of high-pressure seals, with ongoing advancements in materials and sealing technologies ensuring that it remains an innovation and market development center in this field.

Get Customized Report as per Your Business Requirement - Enquiry Now

Some of the major key players in the High-Pressure Seals Market

-

Trelleborg (Hydraulic Seals, O-rings, Rotary Seals)

-

Gallagher Seals (O-rings, Metal Seals, Gaskets)

-

Flowserve Corporation (Mechanical Seals, Seal Support Systems)

-

Performance Sealing Inc. (PSI) (High-Pressure O-rings, Custom Sealing Solutions)

-

Parker Hannifin Corp (Hydraulic Seals, Piston Seals, V-Rings)

-

John Crane (Mechanical Seals, Cartridge Seals)

-

FTL (Hydraulic Seals, High-Pressure PTFE Seals)

-

James Walker (High-Pressure O-rings, Gaskets, Packings)

-

EagleBurgmann (Mechanical Seals, High-Pressure Carbon Seals)

-

Bal Seal Engineering (Spring-Energized Seals, PTFE Seals)

-

Kalsi Engineering, Inc. (Hydrodynamic Seals, Rotary Seals)

-

lli Paris S.r.l. (Custom Sealing Solutions, High-Pressure Seals)

-

SKF (High-Pressure Rotary Seals, Hydraulic Seals)

-

Freudenberg Sealing Technologies (Elastomer Seals, PTFE Seals)

-

Garlock Sealing Technologies (Metal Seals, High-Pressure Gaskets)

-

Saint-Gobain Seals (OmniSeal® PTFE Seals, High-Performance Polymer Seals)

-

Hallite Seals International (Rod Seals, Piston Seals, Wear Rings)

-

Chesterton (Mechanical Seals, Rotary Lip Seals)

-

Techno Ad Ltd. (Custom Rubber Seals, High-Pressure O-Rings)

-

ElringKlinger Kunststofftechnik (Polymer Seals, High-Pressure PTFE Components)

Suppliers for (High-performance sealing solutions for extreme pressure and temperature environments) on High-Pressure Seals Market

-

Performance Sealing Inc

-

Micro Seals

-

Ningbo Bodi Seals Co., Ltd.

-

Steinbach AG

-

Autospin (Oil Seals) Ltd

-

M Barnwell Services

-

American High-Performance Seals

-

Sunbird Seals & Plastics Pvt. Ltd.

-

Senaa Engineering

-

Lineproof Engineering

Recent Development

-

In July 2023: Trelleborg Sealing Solutions, a leading player in the industrial pump sector, introduced the H2Pro range of sealing materials designed for various applications across the hydrogen value chain. This new product line is engineered to provide efficient sealing solutions for high-pressure and extreme-temperature environments, enhancing performance and reliability in demanding conditions.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 5.57 Billion |

| Market Size by 2032 | USD 9.67 Billion |

| CAGR | CAGR of 6.32% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Application (Pumps, Valves, Compressors, Pipes, Ducts) • By Material (Elastomers, PTFE, Metal, Rubber-Metal Combination, Others) • By End Use (Oil & Gas, Aerospace & Defense, Power Generation, Chemical, Automotive, Pharmaceuticals, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Trelleborg, Gallagher Seals, Flowserve Corporation, Performance Sealing Inc. (PSI), Parker Hannifin Corp, John Crane, FTL, James Walker, EagleBurgmann, Bal Seal Engineering, Kalsi Engineering, Inc., lli Paris S.r.l., SKF, Freudenberg Sealing Technologies, Garlock Sealing Technologies, Saint-Gobain Seals, Hallite Seals International, Chesterton, Techno Ad Ltd., ElringKlinger Kunststofftechnik. |