Machine Condition Monitoring Market Size & Overview:

Get more information on Robotic Vision Market - Request Sample Report

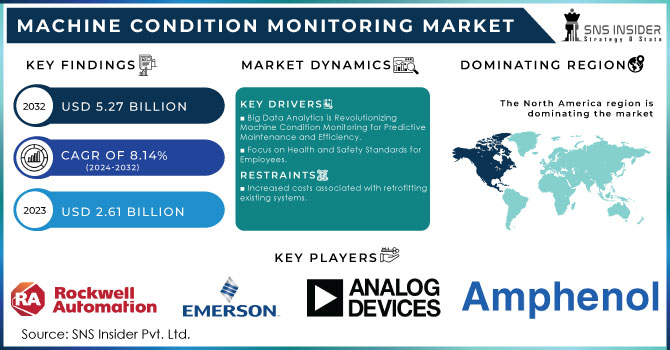

The Machine Condition Monitoring Market size was valued at USD 2.61 Billion in 2023. It is estimated to reach USD 5.27 Billion by 2032, growing at a CAGR of 8.14% during 2024-2032.

The machine condition monitoring market is now a vital industrial sector, supported by the growing demand for efficiency, reliability, and cost savings in equipment. The rise of the machine condition monitoring market is greatly impacted by the growing usage of Industry 4.0 and the Industrial Internet of Things (IIoT). The expansion of Industry 4.0 is fueled by large financial investments, with an estimated global spending of approximately USD 60 billion in 2023. The manufacturing sector depends greatly on sophisticated equipment like CNC machines, conveyors, and industrial robots to keep production flowing. About 70% of manufacturing firms are allocating resources towards Industry 4.0 technologies to improve both operational effectiveness and quality of products. Despite big companies taking the lead, roughly 35% of small and medium-sized businesses (SMEs) are also incorporating Industry 4.0 technologies, showing a wider range of acceptance. With automation and digitalization being adopted globally by industries, the incorporation of advanced sensors, data analytics, and machine learning algorithms into monitoring systems is becoming increasingly common. Manufacturers can detect issues early, plan maintenance during scheduled downtimes, and prevent disruptions by using condition monitoring systems.

AI improves condition-based monitoring by utilizing sophisticated algorithms and machine learning to assess large quantities of data gathered from different sensors. The implementation of AI in maintenance can reduce maintenance costs by up to 20%. This evaluation allows the system to identify patterns and irregularities that could signal potential problems. AI-powered solutions can forecast equipment malfunctions more accurately and quickly than traditional approaches, resulting in improved maintenance tactics. For instance, IBM's Watson IoT platform utilizes AI for predictive maintenance by analyzing sensor data from equipment. This enables businesses to predict potential failures and optimize maintenance schedules, reducing downtime and maintenance costs. The inclusion of AI enables the automation of monitoring tasks, ensuring constant monitoring of equipment health without the requirement of human involvement. This leads to enhanced operational efficiency and decreased human error. Moreover, AI can improve maintenance plans by forecasting when machinery will need maintenance, leading to reduced unnecessary checkups and longer equipment lifespan. AI supports businesses in improving equipment reliability, cutting costs, and boosting overall operational performance through actionable insights and automated monitoring tasks.

Machine Condition Monitoring Market Dynamics:

Drivers

-

Big Data Analytics is Revolutionizing Machine Condition Monitoring for Predictive Maintenance and Efficiency.

The rise of Big Data Analytics is a key factor in driving the Machine Condition Monitoring Market. Big Data Analytics allows for the examination and interpretation of large volumes of data produced by machines and industrial systems, providing access to insights that were previously out of reach. With the rising adoption of smart manufacturing and the IIoT, machines now come equipped with various sensors to continually track factors like temperature, vibration, and pressure. When combined and examined, the data from this sensor can uncover trends and irregularities that suggest wear and tear on the machine, possible breakdowns, or inefficiencies. The use of Big Data Analytics enables the immediate examination of the data, which results in the development of maintenance strategies that can predict future issues. Industries no longer need to stick to scheduled maintenance; instead, they can predict failures in advance to decrease downtime and maintenance expenses substantially. Furthermore, it helps improve machine efficiency and prolong equipment lifespan through actionable insights derived from historical data patterns.

-

Focus on Health and Safety Standards for Employees.

Employee health and safety standards are essential in the Machine Condition Monitoring (MCM) market. Businesses are striving to improve workplace safety and reduce risks related to machine operations through the adoption and advancement of MCM technologies. Machine Condition Monitoring is the ongoing evaluation of equipment to identify and resolve possible problems before they become serious. This proactive strategy not only increases the durability of equipment but also greatly lowers the likelihood of accidents and injuries. By incorporating MCM systems, businesses can guarantee proper operation of machinery, thus averting dangerous malfunctions that may result in safety incidents. Adherence to health and safety rules requires employers to put in place safeguards for their employees. MCM systems help with compliance by allowing for real-time monitoring of equipment conditions, detecting signs of deterioration, and arranging maintenance when needed. This helps decrease the chances of sudden malfunctions that could potentially create safety hazards.

Restraints

-

Increased costs associated with retrofitting existing systems.

Higher expenses linked to updating current systems are a major obstacle in the Machine Condition Monitoring Market. Retrofitting includes enhancing or adjusting current machinery and systems to incorporate advanced condition monitoring technologies. Although these enhancements may improve the system's performance and reliability, the associated expenses may be too high for numerous organizations. The retrofitting process involves purchasing new sensors and monitoring equipment, as well as extensive installation and integration efforts. This involves adjusting the new systems to function smoothly with outdated equipment, which frequently necessitates specific skills and technical know-how. The expenses can increase even more due to the requirement of system downtime for installation, resulting in possible production setbacks. Furthermore, the intricacy of retrofitting may lead to unforeseen costs for adjusting the current infrastructure to support new technologies. Organizations could encounter difficulties like incompatibility between old and new parts or the requirement for extra changes to current systems. These factors add to a substantial financial load, posing a challenge for businesses to rationalize investing in upgrades for condition monitoring.

Machine Condition Monitoring Market Segment Overview:

By Technique

Vibration monitoring captured 35% of revenue share in 2023 and dominated the market. This method is essential for identifying disparities, misalignments, and other mechanical problems in rotating equipment such as motors, pumps, and turbines. Through the analysis of vibration data, organizations can anticipate equipment malfunctions and conduct maintenance before expensive breakdowns take place. Sectors like oil and gas, manufacturing, and power generation depend greatly on vibration monitoring for maintaining efficiency and minimizing downtime. General Electric (GE) utilizes vibration monitoring extensively in its power plants as a means of ensuring the reliability of turbines and generators.

Ultrasound Emission Monitoring is going to be the fastest-growing segment during the forecast period 2024-2032, as it can identify faults and energy inefficiencies in their early stages, which other techniques may overlook. This method works well at spotting problems in compressed air systems, steam traps, and electrical equipment, so it is widely used in industries that prioritize energy efficiency and sustainability. Businesses are increasingly utilizing ultrasound emission monitoring for predictive maintenance because it enables non-intrusive inspections during equipment operation. Emerson Electric Co. uses ultrasound technology in its machinery health solutions to assist customers in the automotive and aerospace industries by identifying leaks, bearing failures, and electrical faults at an early stage.

By Deployment

The On-Cloud segment led the market in 2023 with a 55% market share, due to its scalability, flexibility, and cost-effectiveness. Cloud-based solutions provide the ability to access real-time data remotely, improving the monitoring and management of machine statuses. The section gains from progress in cloud computing and IoT technologies that improve the precision and timeliness of condition monitoring. GE Digital uses cloud-based technology for its Predix platform, providing real-time monitoring of machines and predictive analysis. This system assists in enhancing machine efficiency and avoiding breakdowns by analyzing information gathered from different sensors in industries.

The On-Premises segment is expected to grow at a faster CAGR during the forecast period. Organizations that choose on-premises solutions enjoy keeping their data in their infrastructure, which is important for compliance and security purposes. Siemens offers on-site condition monitoring solutions with its Siemens Condition Monitoring System, providing extensive diagnostic and monitoring features for industrial equipment. This system is utilized in settings that necessitate strict data security and operational management.

By Process

Online Condition Monitoring captured a major market share of more than 54% in 2023. This includes placing sensors and monitoring systems on equipment to continuously analyze variables like vibration, temperature, and acoustic emissions. This method enables the detection of possible problems at an early stage, reducing downtime and improving maintenance schedules. The section is influential because it offers ongoing insights, improving predictive maintenance tactics and minimizing unforeseen breakdowns.

Portable Condition Monitoring is the practice of utilizing handheld or portable gadgets to evaluate the state of equipment at different spots or moments. This approach is commonly utilized for scheduled checks as opposed to constant surveillance. It enables maintenance staff to conduct thorough inspections and diagnostic assessments, offering versatility in overseeing different machines without requiring a permanent setup. While not as consistent as online systems, it provides a cost-efficient alternative for smaller businesses or for evaluating equipment that doesn't require constant monitoring.

Get Customized Report as per your Business Requirement - Request For Customized Report

Machine Condition Monitoring Market Regional Analysis:

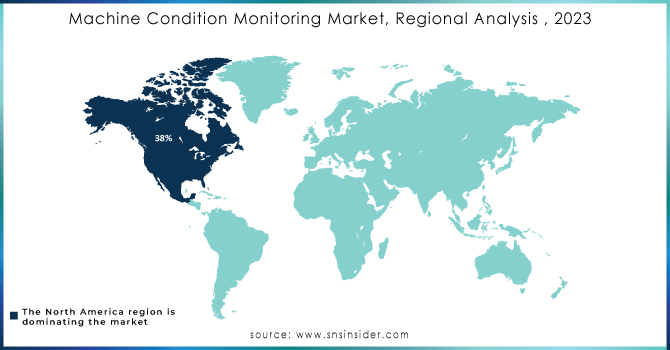

North America dominated the market in 2023 with a revenue share of 38%, due to its sophisticated industrial foundation and quick acceptance of state-of-the-art technologies. The area's focus on using predictive maintenance to decrease downtime and enhance operational efficiency in industries like oil and gas, aerospace, and manufacturing has increased the need for machine condition monitoring systems. The market is further reinforced by the participation of major companies such as General Electric, Emerson Electric, and Honeywell in the United States. These businesses provide cutting-edge solutions like vibration monitoring and infrared thermography to assist companies in reaching optimal machine performance.

Asia-Pacific is accounted to have a faster growth rate during 2024-2032, due to quick industrialization and infrastructure development in countries such as China, India, and Japan. The growth of the manufacturing industry in the area, along with a growing understanding of the advantages of predictive maintenance, is driving the utilization of machine condition monitoring solutions. Major sectors such as automobile, energy production, and chemical industries are putting money into these technologies in order to boost efficiency and lower operational expenses. Corporations such as SKF and Siemens have been actively implementing their condition-monitoring solutions in the area, meeting the increasing need for real-time data analysis and remote monitoring.

KEY PLAYERS:

The key players in the Global Machine Condition Monitoring market are Emerson Electric Co, Rockwell Automation Inc, Analog Devices Inc, Amphenol Inc., National Instruments Corp, Fluke Corporation, General Electric, Parker Hannifin Corp, SKF, Allied Reliability, Meggitt PLC and other.

Recent Development

-

In January 2024, SKF launched the Enlight AI machine condition monitoring system, which utilizes artificial intelligence to predict equipment failures before they happen. This system is designed to improve efficiency and reduce downtime in industrial applications by continuously monitoring machine health.

-

In September 2024, Fluke introduced the 3561 FC vibration sensor as part of its connected reliability ecosystem. This sensor monitors vibration levels in industrial equipment, allowing maintenance teams to detect early signs of mechanical issues and schedule repairs before they escalate.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 2.61 Billion |

| Market Size by 2032 | USD 5.27 Billion |

| CAGR | CAGR of 8.14% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Technique (Vibration Monitoring, Thermography, Oil Analysis, Corrosion Monitoring, Ultrasound Emission Monitoring, Motor Current Analysis) • By Deployment (On-Cloud, On-Premises) • By Process (Online Condition Monitoring, Portable Condition Monitoring) • By Industry (Oil & Gas, Metal & Mining, Automotive, Food & Beverages, Power Generation, Chemicals, Aerospace, Marine, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Emerson Electric Co, Rockwell Automation Inc, Analog Devices Inc., Amphenol Inc., National Instruments Corp, Fluke Corporation, General Electric, Parker Hannifin Corp, SKF, Allied Reliability, Meggitt PLC |

| Key Drivers | • Big Data Analytics is Revolutionizing Machine Condition Monitoring for Predictive Maintenance and Efficiency. • Focus on Health and Safety Standards for Employees. |

| Restraints | • Increased costs associated with retrofitting existing systems. |