Mirror Coatings Market Report Scope & Overview:

Get More Information on Mirror Coatings Market - Request Sample Report

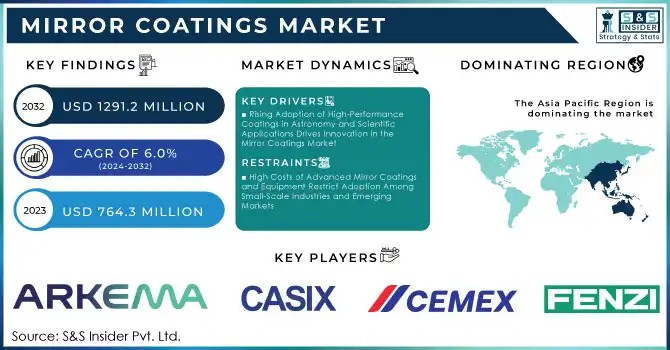

The Mirror Coatings Market Size was valued at USD 764.3 million in 2023 and is expected to reach USD 1291.2 million by 2032 and grow at a CAGR of 6.0% over the forecast period 2024-2032.

The mirror coatings market is driven by advancements in material sciences and growing applications across industries such as automotive, aerospace, construction, and astronomy. Innovations in coating technologies are addressing the demand for enhanced durability, reflectivity, and functionality in mirrors used in these sectors. Recent developments underscore the importance of cutting-edge mirror coatings. For instance, in May 2024, a significant milestone was achieved with the Rubin Observatory applying its first reflective coating to its primary mirror. This effort underscores the advancements in large-scale optical coatings designed for precision in astronomical observations. Similarly, the Vera Rubin Observatory introduced a reflective coating to its primary mirror during the same month, highlighting the increasing investment in high-performance mirror coatings to support next-generation telescopes.

The aerospace and defense sectors are also benefiting from mirror coating innovations. In December 2023, an advanced mirror-like coating was unveiled for the F-35C fighter aircraft aboard the USS Abraham Lincoln. This development exemplifies how such coatings are being optimized for stealth and performance enhancements in military applications. Collectively, these initiatives demonstrate how companies are leveraging advanced technologies to meet diverse industry needs, driving the mirror coatings market forward with solutions tailored to precision, efficiency, and durability.

Mirror Coatings Market Dynamics:

Drivers:

-

Rising Adoption of High-Performance Coatings in Astronomy and Scientific Applications Drives Innovation in the Mirror Coatings Market

The growing investments in scientific research and development are propelling the demand for high-performance mirror coatings, particularly in astronomy. Advanced coatings that enhance reflectivity and durability are critical for telescopes and observatories, ensuring precision in celestial observations. Projects like the Vera Rubin Observatory's primary mirror coating exemplify this trend. These innovations cater to the need for improved optical performance and longer service life, pushing manufacturers to innovate and expand their offerings. This demand aligns with increasing space exploration initiatives globally, establishing astronomy as a significant driver for the mirror coatings market.

-

Growing Use of Mirror Coatings in Automotive and Aerospace Sectors Enhances Market Potential Across Industrie0073

-

Increased Application of Energy-Efficient Mirror Coatings in Construction Industry Accelerates Market Growth

-

Technological Advancements in Deposition Techniques Boost Precision and Quality in Mirror Coatings

-

Rising Focus on Sustainable and Eco-Friendly Mirror Coating Solutions to Align with Environmental Norms

Restraint:

-

High Costs of Advanced Mirror Coatings and Equipment Restrict Adoption Among Small-Scale Industries and Emerging Markets

High costs associated with advanced mirror coatings and the specialized equipment required for their production act as a significant restraint for the mirror coatings market, particularly for small-scale industries and emerging markets. The development of high-performance coatings involves the use of premium raw materials, precision technologies such as chemical vapor deposition or sputtering, and advanced machinery, all of which increase production costs. Small-scale manufacturers and businesses in cost-sensitive regions often face challenges in affording these technologies, limiting their ability to compete with larger companies. Additionally, the need for skilled labor and adherence to stringent quality standards further adds to the operational expenses, making it difficult for smaller players to justify the investment. This cost barrier not only restricts the adoption of advanced mirror coatings but also slows market penetration in regions with constrained industrial budgets, impacting the overall market growth potential.

Opportunity:

-

Rising Investments in Space Exploration and Satellite Programs Open New Avenues for High-Performance Mirror Coatings

Emerging economies, particularly in Asia-Pacific, Latin America, and parts of Africa, represent untapped opportunities for the extruder market. As industrialization continues in these regions, the demand for extruded products in various sectors such as automotive, construction, and packaging is on the rise. With rapid urbanization and increased infrastructure development, emerging economies are poised to become key markets for extrusion technologies. Furthermore, the growing middle class in these regions is driving demand for consumer goods that require extruded materials, such as packaging for food, electronics, and personal care products. Companies looking to expand their market share can benefit from targeting these regions, where there is a growing need for both standard and customized extrusion solutions. The rise of manufacturing facilities in emerging markets, coupled with supportive government policies to boost local production, is expected to fuel the growth of the Mirror Coatings market in these regions.

-

Growing Adoption of Smart Mirrors in Commercial and Residential Sectors Expands Application Scope for Mirror Coatings

-

Development of Multifunctional Mirror Coatings for Healthcare and Biomedical Applications Creates Emerging Opportunities in Specialized Markets

Multifunctional mirror coatings are opening new horizons in healthcare and biomedical applications, where precision and hygiene are paramount. These coatings are used in medical devices, surgical instruments, and diagnostic equipment to enhance optical clarity and ensure sterility. Innovations in anti-reflective and antimicrobial coatings are particularly gaining traction, addressing the unique needs of medical environments. For example, high-performance coatings that reduce light scattering and glare improve the accuracy of imaging systems and diagnostic tools. As the healthcare industry continues to grow, fueled by advancements in medical technology and increased patient demand, the need for coatings that combine functionality with stringent hygiene standards is expected to expand, creating niche opportunities for manufacturers in this field.

Challenge:

-

Stringent Environmental Regulations and Sustainability Requirements Pose Challenges in Manufacturing Advanced Mirror Coatings

Environmental regulations and the rising focus on sustainability pose significant challenges for mirror coating manufacturers, impacting production processes and material choices. These regulations often require manufacturers to reduce volatile organic compound (VOC) emissions, use eco-friendly materials, and adopt energy-efficient production techniques, all of which can increase operational costs and complexity. Meeting these requirements demands substantial investment in research and development to create coatings that meet both performance and environmental standards. Moreover, transitioning existing production lines to comply with these norms often involves significant capital expenditure, making it particularly burdensome for small and mid-sized manufacturers. Balancing the high-performance requirements of industries such as aerospace, automotive, and construction with the need for sustainability is a complex task, and failure to comply with regulatory standards can lead to fines or loss of market access. This dual pressure of regulatory compliance and maintaining competitive pricing remains a critical challenge for the mirror coatings market.

| Technology Trend | Description | Example Applications | Impact on Market |

|---|---|---|---|

| Anti-Reflective Coatings | Coatings are designed to reduce glare and reflection, enhancing optical clarity and visibility. | Telescopes, cameras, optical instruments, automotive mirrors. | Increased adoption in industries requiring high-precision optics. Significant growth in demand from the optics and automotive sectors. |

| Self-Cleaning Coatings | Coatings that allow mirrors to remain clean by using hydrophobic and oleophobic properties to repel water and dirt. | Architectural mirrors, automotive side mirrors, outdoor signage. | Growth in demand is driven by convenience, especially in high-maintenance environments like buildings and vehicles. |

| Infrared Reflective Coatings | Coatings that improve energy efficiency by reflecting infrared light while maintaining optical clarity. | Solar panels, energy-efficient windows, automotive windshields. | Adoption of renewable energy and energy-efficient technologies, creating new opportunities in the construction and automotive sectors. |

| Durable Coatings for Harsh Environments | Advanced coatings are designed to withstand extreme conditions, including UV radiation, high temperatures, and corrosive environments. | Aerospace, defense, industrial applications, telescopes. | Strong demand from the aerospace and defense industries, as well as applications in high-temperature environments. |

| Multifunctional Coatings | Coatings that combine multiple properties, such as anti-reflective, scratch-resistant, and self-healing features, into one coating. | Smart mirrors, healthcare diagnostic tools, and consumer electronics. | Significant rise in demand due to increased use of smart technologies and consumer electronics. Provides added value in diverse applications. |

| Nanotechnology-based Coatings | Coatings incorporating nanomaterials to achieve enhanced optical properties, increased durability, and functionality at a microscopic scale. | High-precision mirrors for telescopes, high-performance optics. | Continuous innovation due to the demand for high-performance optical systems and growing interest in nano-based solutions. |

| Metallic Coatings | Metal-based coatings are often applied to mirrors to enhance reflectivity and provide durability against wear and corrosion. | Automotive mirrors, satellite components, and reflectors in optical telescopes. | Demand is driven by the need for high reflectivity in industries like automotive and aerospace. |

Mirror Coatings Market Segmentation Overview

By Type

In 2023, the Polyurethane resin segment dominated the Mirror Coatings Market, accounting for approximately 40% of the market share. Polyurethane resin is favored for its durability, resistance to environmental factors, and ability to provide a high-quality finish that enhances the reflective properties of mirrors. This resin is particularly popular in automotive and architectural applications, where both aesthetic appeal and longevity are crucial. For example, polyurethane-based coatings are used extensively in car side mirrors, providing enhanced durability against wear and tear while maintaining excellent optical clarity.

By Technology

The Water-based technology segment dominated the Mirror Coatings Market in 2023, capturing 45% of the market share. Water-based coatings are environmentally friendly, with low levels of volatile organic compounds (VOCs), making them a preferred choice for eco-conscious consumers and industries. They offer a combination of ease of application and excellent performance in creating durable, reflective surfaces, particularly in the architectural sector. For example, water-based mirror coatings are commonly used in interior decor and home furnishings due to their sustainability benefits and high-quality finish.

By End-Use Industry

The Architectural segment dominated the Mirror Coatings Market in 2023, with a market share of 35%. Architectural applications, particularly in interior design and construction, require mirrors with superior reflectivity and resistance to degradation over time. These coatings are widely used in decorative mirrors, glass facades, and other architectural elements. The increasing demand for modern architectural aesthetics, such as mirrored facades and decorative wall mirrors in commercial buildings and residential properties, drove this growth.

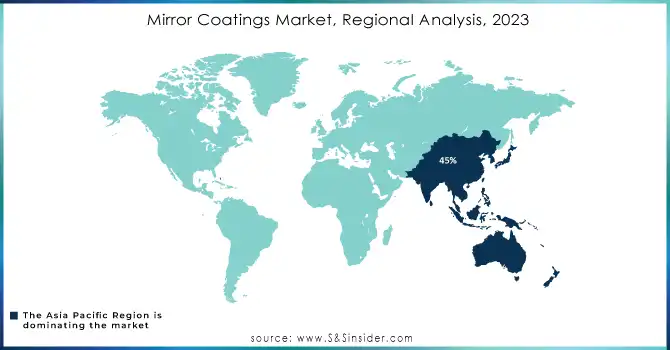

Mirror Coatings Market Regional Analysis

In 2023, Asia Pacific dominated the Mirror Coatings Market, accounting for 45% of the market share. The region's dominance is primarily driven by the rapid growth of end-use industries like automotive, architecture, and solar power in countries like China, Japan, and India. In China, the automotive industry is a major contributor, with the demand for high-quality mirror coatings in vehicles increasing due to the country's booming car manufacturing sector. The rise in urbanization and infrastructure development in India and China has also led to a surge in the demand for architectural mirrors. Japan, on the other hand, has a strong presence in high-end mirror coatings, particularly for decorative and electronic applications. For example, China’s automotive industry produced over 25 million vehicles in 2023, contributing significantly to the growth of mirror coatings used in automotive side and rearview mirrors. This is further supported by the growing popularity of solar power, where mirror coatings are essential for improving the reflectivity and efficiency of solar panels in countries like India. The region’s robust industrial base, along with increasing technological advancements, ensures its market leadership.

The North American region, emerged as the fastest-growing region and is expected to grow with a CAGR of 6.5% from 2024 to 2032. This growth can be attributed to the rising demand for mirror coatings in the automotive and architectural sectors, alongside increasing investments in renewable energy, particularly in solar power. In the United States, there is a significant push towards green building initiatives, with more construction projects incorporating reflective materials like mirror coatings in both residential and commercial buildings. Additionally, the automotive market in North America remains strong, with major players like General Motors and Ford investing in advanced mirror technologies to improve vehicle aesthetics and functionality. For instance, in 2023, North America accounted for about 14.5 million vehicle sales, where mirror coatings are increasingly used in car side mirrors and rearview mirrors. Canada’s growing focus on solar energy also contributes to the rise in demand for mirror coatings, with initiatives such as the “Green Energy Act” driving investments in solar power infrastructure. The combination of these factors ensures that North America remains the fastest-growing region, bolstered by increased technological advancements and rising consumer demand for high-quality, sustainable coatings.

Get Customized Report as per your Business Requirement - Request For Customized Report

Key Players in Mirror Coatings Market

-

Arkema Group (Rilsan, Kynar PVDF)

-

Casix, Inc. (Casix Coatings, Casix Mirror Coatings)

-

Cemex S.A.B. de C.V. (Cemex Reflective Coatings, Cemex Mirror Glass)

-

Diamon-Fusion International, Inc. (Diamon-Fusion Coating, DF-Xtra Coating)

-

FENZI S.p.A (Mirroflex, Fenzi Mirror Coatings)

-

Ferro Corporation (Mirror Silver, Ferro Mirror Coatings)

-

Glas Trosch Holding AG (Mirrorglass, Glass Reflective Coatings)

-

Guardian Glass (Guardian CrystalClear, SunGuard)

-

Mader Group (Mader Mirror Coating, Mader Clear Coatings)

-

Pearl Nano, LLC (Pearl Nano Mirror Coating, Nano Coating)

-

3M Company (3M Mirror Film, 3M Scotchgard Glass Coating)

-

AkzoNobel N.V. (Interpon Mirror Coating, AkzoNobel Mirror Coatings)

-

BASF SE (BASF Glass Coating, BASF Reflective Coating)

-

Bystronic Glass GmbH (Bystronic Glass Mirror Coating, Bystronic Coating Systems)

-

Chemours Company (Opteon Mirror Coating, Chemours Reflective Coatings)

-

Dupont de Nemours, Inc. (DuPont Tedlar, DuPont Reflective Coatings)

-

Eastman Chemical Company (Eastman Coatings, Eastman Mirror Coating Solutions)

-

Jotun A/S (Jotun Mirror Coatings, Jotun Reflective Coatings)

-

PPG Industries, Inc. (PPG Mirror Coatings, PPG Sun Control)

-

Sherwin-Williams Company (Sherwin-Williams Mirror Coatings, Sherwin-Williams Reflective Coatings)

Raw Material Suppliers:

-

Ferro Corporation

-

BASF SE

-

Chemours Company

-

Arkema Group

-

Eastman Chemical Company

-

Dow Chemical Company

-

Huntsman Corporation

Equipment Manufacturers:

-

Mader Group

-

Glas Trosch Holding AG

-

Bystronic Glass GmbH

-

SCHOTT AG

-

Applied Materials, Inc.

-

Bohle Group

End-users (OEMs):

-

VELUX Group (Roof windows)

-

Cemex S.A.B. de C.V. (Construction materials)

-

Saint-Gobain (Construction and building materials)

-

Toyota (Automotive)

-

Ford (Automotive)

-

General Motors (Automotive)

Recent Developments

-

April 2024: Guardian Glass introduced Guardian CrystalClear, a reduced-iron glass that offered 67% greater color neutrality and 90% visible light transmission. This product improved clarity and color neutrality, making it suitable for various architectural applications. It was compatible with Guardian SunGuard low-E coatings and available in multiple thicknesses and jumbo sizes.

-

March 2024: Guardian Glass and the VELUX Group entered a joint development agreement to advance tempered vacuum-insulated glass (VIG) technology. The partnership combined their expertise, technical teams, and intellectual property to meet the growing demand for VIG and integrate it into VELUX's roof window products.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | US$ 764.3 Million |

| Market Size by 2032 | US$ 1291.2 Million |

| CAGR | CAGR of 6.0% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | •By Type (Polyurethane resin, Epoxy resin, Acrylic resin, Others) •By Technology (Water-based, Solvent-based, Nanotechnology-based) •By End-use Industry (Architectural, Automotive & Transportation, Decorative, Solar power, Others |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe [Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Casix, Inc., Guardian Glass, Cemex S.A.B. de C.V., Mader Group, Diamon-Fusion International, Inc., FENZI S.p.A, Pearl Nano, LLC, Ferro Corporation,Arkema Group, Glas Trosch Holding AG and other key players |

| Key Drivers | • Increased Application of Energy-Efficient Mirror Coatings in Construction Industry Accelerates Market Growth • Technological Advancements in Deposition Techniques Boost Precision and Quality in Mirror Coatings |

| RESTRAINTS | • High Costs of Advanced Mirror Coatings and Equipment Restrict Adoption Among Small-Scale Industries and Emerging Markets |