Powder Coating Equipment Market Report Scope & Overview:

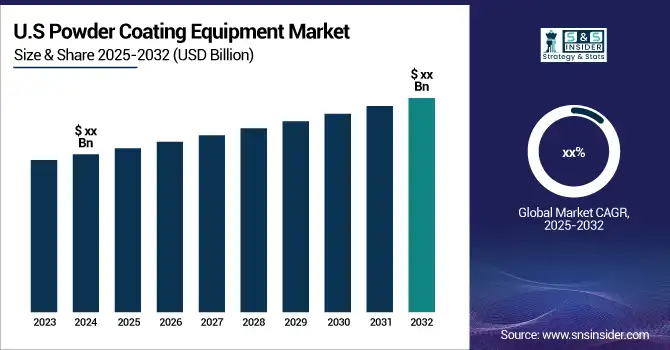

The Powder Coating Equipment Market Size was estimated at USD 2.27 billion in 2024 and is expected to arrive at USD 3.11 billion by 2032 with a growing CAGR of 3.99% over the forecast period 2025-2032. This report offers unique insights into the Powder Coating Equipment Market by analyzing production capacity and utilization rates across key regions, along with equipment efficiency and downtime metrics to assess operational performance.

To Get more information on Powder Coating Equipment Market - Request Free Sample Report

It highlights technological advancements and automation adoption trends by region, showcasing the shift towards AI-driven and robotic coating systems.

Market Size and Forecast:

-

Market Size in 2024: USD 2.27 Billion

-

Market Size by 2032: USD 3.11 Billion

-

CAGR: 3.99% from 2025 to 2032

-

Base Year: 2024

-

Forecast Period: 2025–2032

-

Historical Data: 2021–2023

Key Powder Coating Equipment Market Trends

-

Rising demand for low-cost chipless RFID solutions to enable affordable high-volume tagging.

-

Growing integration of RFID with smart packaging for real-time tracking and consumer engagement.

-

Advancements in printed electronics are improving the cost-efficiency and scalability of RFID tags.

-

Increasing focus on sustainable and eco-friendly materials to meet green regulations.

-

Expanding adoption in retail and apparel to enhance inventory accuracy and reduce shrinkage.

-

Accelerated use of RFID in healthcare for asset tracking and patient safety compliance.

Powder Coating Equipment Market Growth Drivers

-

The powder coating equipment market is growing due to increasing demand for durable, eco-friendly coatings with superior corrosion resistance across various industries.

The preference towards powder coatings is attributed to their longer life, impact resistance, and enhanced finish quality as compared to traditional liquid coatings. Moreover, strict environmental legislation instituted to cut VOC emissions has hastened the migration to green, solvent-free coating alternatives. As technology progresses, more manufacturers are adopting automated and robotic powder coating systems that improve efficiency, conserve material, and guarantee precision in their processes. The advent of low-temperature cure powders is also unlocking new avenues with the ability to coat heat-sensitive materials, such as plastics and composites. In addition, demand is driven by rapid industrial development and infrastructure in emerging economies. While the outlook is encouraging, there are many challenges in the market such as high initial investment, and the complexity of colour matching. Further barriers include fluctuating raw material prices and competition from opposing coating technologies. Nevertheless, the industry will likely experience stable growth with a growing interest in sustainability, cost-efficiency and tape's overall coating performance. High level of awareness coupled with growing application in end-use industries is expected to drive the growth of global powder coating equipment market in the coming years.

Powder Coating Equipment Market Restraints

-

Setting up a powder coating facility requires high capital investment in equipment, infrastructure, and compliance with safety and environmental regulations.

Setting up a powder coating facility requires a significant initial investment, primarily due to the cost of specialized equipment, infrastructure, and technology. Basic equipment like spray booths, curing ovens, powder application guns, and recovery systems can get expensive, especially for automated setups. In addition, facilities must also have adequate ventilation, temperature control, and safety measures to meet environmental and workplace standards. Advanced electrostatic spraying systems often require expensive inputs as do robotic automation systems. Small and medium-sized enterprises (SMEs) may not have the capital to invest this way, which restricts market entry for new entrants. In addition, ongoing maintenance, skilled labor training, and certifications add to the financial burden. These costs are offset in the long term due to the low material wastage, low operational costs, and a high-quality finish that ensures that it is perfect for those businesses that desire durability and environmental sustainability.

Powder Coating Equipment Market Opportunities

-

The rising use of powder coatings in appliances, furniture, and electronics is driven by their durability, eco-friendliness, and superior finish.

The growing adoption of powder coatings in the consumer goods sector is creating new opportunities in the market. Driven by their durability, scratch and corrosion resistance, as well as their environmentally friendly properties, appliances, furniture, and electronics are increasingly coated with powder coatings. These include home appliances such as fridges, ovens and washing machines with powder-coated surfaces for both durability and good looks. Powder coatings are also applied on metal frames of office furniture, outdoor furnishings, etc. in the furniture industry, improves durability and color retention. In the electronics sector, powder coatings are also becoming increasingly popular for enclosures and components, providing heat stability and electrical insulation. The increasing adoption of powder coatings owing to their replacement of solvent-based coatings also boosts demand for eco-friendly coatings as these are free from volatile organic compounds (VOCs). As consumers become increasingly aware of the sustainability and longevity of products, manufacturers are investing in modern powder coat technologies, which further drives market growth.

Powder Coating Equipment Market Challenges

-

Regulatory compliance complexity arises as manufacturers must adapt to varying environmental and safety regulations across different regions, increasing costs and operational challenges.

Regulatory compliance complexity is a significant challenge in the powder coating equipment market, as different regions impose varying environmental and safety regulations. Governments throughout the world have strict policies regarding volatile organic compound (VOC) emissions, workplace safety, and hazardous material handling, and manufacturers must change their processes to meet these requirements on an ongoing basis. The Environmental Protection Agency (EPA) in the U.S. and the Environmental Protection Act and the Occupational Safety and Health Administration (OSHA) also formulate stringent guidelines to control the exposure to hazardous chemicals, and similarly, REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation in Europe implements strict regulations on the use of these chemicals. In a similar vein, Asian markets feature emerging regulatory regimes which will require adherence to sustainability and worker protection standards. Operating within these varied regulations raises operation costs and necessitates additional research, development, and certification investment from companies. If ignored, legal penalties, production delays and restrictions on market access can follow. Manufacturers will be competing with even more companies for the same limited resources, so they need to embed environmentally friendly technologies and global safety standards into their products and develop agile strategies that can work across long regulatory regimes.

Powder Coating Equipment Market Segment Analysis

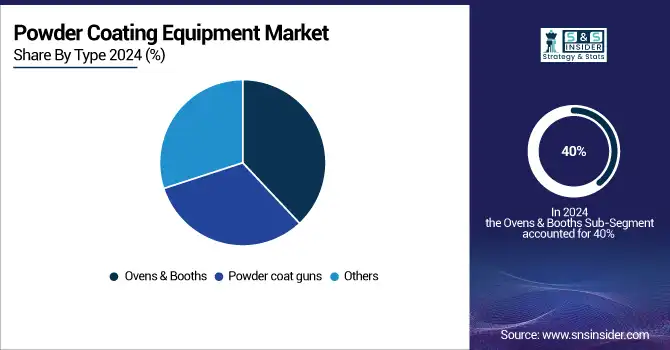

By Type

The Ovens & Booths segment dominated with a market share of over 40% in 2024, due to its critical role in the coating process. Ovens cure powder coats and ensure a strong and superior finish, while booths provide an optimized and clean environment for powder coating application. They are extensively utilized in industries including automotive, aerospace, and general manufacturing, where high-volume production requires accurate and uniform coating solutions. Moreover, the development of energy-efficient and high-performance curing ovens has also propelled the growth of the market. This factor also bolsters the segment's dominance as industries look to improve productivity, lower operational costs, and increase compliance with processes and coatings in a way that maintains or improves coating quality and environmental quality.

By Application

The Consumer Goods segment dominated with a market share of over 32% in 2024, owing to the increasing demand for high-quality, durable auxiliary and decorative finishes on products such as home appliances, electronics, and fitness equipment. Powder coating provides better corrosion, chemical, and wear resistance than traditional paint, making it a popular choice among manufacturers seeking to improve the durability and appearance of their products. Its eco-friendly qualities too, including low emissions of volatile organic compounds (VOC) and lower waste, push for adoption. This is further supported by the rising disposable income levels as well as changing consumer preferences toward premium and long-lasting products. Continuously growing coating technologies and automation in the powder coating industries ensure a substantial segment of the consumer goods market about the steady perpetuity of powder coating consumables.

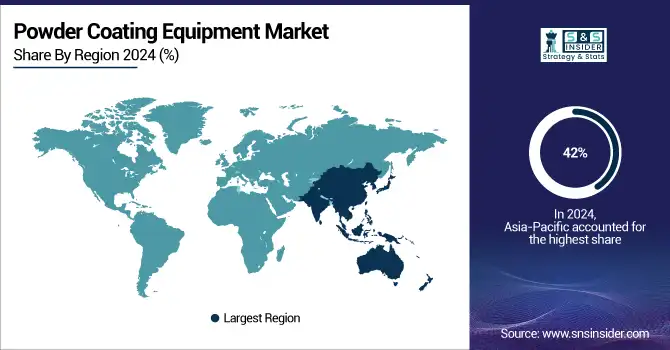

Powder Coating Equipment Market Regional Analysis

Asia Pacific Powder Coating Equipment Market Insights

The Asia-Pacific region dominated with a market share of over 42% in 2024, driven by rapid industrialization and expanding manufacturing sectors. These markets will witness exceptional growth in various end-use sectors such as automotive, consumer goods, and construction, such as countries like India, China, and Japan, which is expected to fuel the demand for durable and efficient coating solutions. The region's low production costs, a rising middle class, and increasing investment in infrastructure are all helping to stimulate the market's expansion. Further, growing awareness about green coatings and supportive government initiatives favoring sustainable industrial practices are accelerating the adoption of powder coating equipment. This trend strengthened the North America market position, making Asia-Pacific with its wide variety of ice cream, major manufacturers, suppliers, and research institutions the most important contributor (influencer) to the international powder coating equipment market.

Get Customized Report as per Your Business Requirement - Enquiry Now

Europe Powder Coating Equipment Market Insights

Europe is the fastest-growing region in the Powder Coating Equipment Market, driven by stringent environmental regulations that promote eco-friendly coating solutions. Rising adoption of sustainable coatings, especially in automotive, construction, and furniture industries, is supporting the market growth. Also, the demand for liquid coatings is being replaced by powder coatings owing to low volatile organic compounds emissions and high durability. Moreover, emerging developments in coating systems, such as the automation and accuracy application technologies, are also eradicating inefficiency and reducing material waste. Top players in Europe are investing in R&D to launch energy-efficient and high-performance coating systems. According to the report, the demand for corrosion-resistant coatings is significantly rising in the region owing to growing focus on sustainability, and this is likely to boost market growth significantly shortly.

North America Powder Coating Equipment Market Insights

The North America Powder Coating Equipment Market is witnessing steady growth in 2025, driven by the region’s well-established manufacturing, automotive, and industrial sectors. The U.S. and Canada are leading adopters of advanced powder coating equipment to enhance production efficiency, ensure high-quality finishes, and comply with stringent environmental regulations. Increasing demand for durable and eco-friendly coatings, coupled with investments in smart manufacturing and automation technologies, is boosting market growth. Moreover, collaborations between equipment manufacturers and industrial end-users are accelerating the adoption of innovative powder coating solutions across the region.

Latin America (LATAM) Powder Coating Equipment Market Insights

The LATAM Powder Coating Equipment Market is gradually expanding in 2025, supported by the region’s emerging automotive, construction, and industrial manufacturing sectors. Countries like Brazil and Mexico are witnessing increasing adoption of advanced powder coating systems to improve product quality, reduce operational costs, and comply with environmental standards. Local distributors and service providers are partnering with global technology companies to access state-of-the-art coating equipment and technical support. Government initiatives promoting industrial modernization and export competitiveness are further contributing to market growth across the region.

Middle East & Africa (MEA) Powder Coating Equipment Market Insights

The MEA Powder Coating Equipment Market is gaining traction in 2025, driven by industrial diversification and rising demand for high-quality and durable coating solutions. Countries including the UAE, Saudi Arabia, and South Africa are deploying advanced powder coating systems in automotive, construction, and heavy machinery sectors. Expansion of industrial hubs, adoption of modern manufacturing practices, and the presence of international equipment providers are encouraging investments in advanced powder coating infrastructure. Additionally, initiatives to adhere to global quality and environmental standards are propelling the regional market growth.

Powder Coating Equipment Market Competitive Landscape

Xtrutech Ltd

Xtrutech Ltd is a leading provider of extrusion and material handling equipment, specializing in solutions that enhance manufacturing efficiency and product quality across industries such as plastics, chemicals, and food processing. The company focuses on delivering innovative extruder lines, cooling systems, and integrated automation solutions to optimize production processes.

-

In June 2024, Xtrutech Ltd launched the XTDC2, a drum cooler with interchangeable configurations. Designed for seamless integration, it can be paired with Xtrutech’s XTS24 twin-screw extruder to enhance the efficiency of extruder lines.

Hillenbrand Inc. (Coperion GmbH)

Hillenbrand Inc., through its subsidiary Coperion GmbH, is a global provider of bulk material handling, processing, and powder coating equipment. The company offers advanced extrusion, feeding, and weighing technologies for industries including plastics, chemicals, and food, aiming to improve operational efficiency and product consistency.

-

In May 2023, Hillenbrand Inc. (Coperion GmbH) acquired Schenck Process FPM to integrate advanced technologies into its equipment. This strategic acquisition is expected to strengthen the company’s product portfolio and expand its footprint in the powder coating equipment market.

Powder Coating Equipment Market Key Players

Some of the major key players in the Powder Coating Equipment Market

-

Reliant Finishing Systems (Powder Coating Ovens, Booths, Guns)

-

Oven Empire Manufacturing (Industrial Ovens, Powder Coating Booths)

-

Mitsuba Systems Pvt. Ltd. (Powder Coating Guns, Booths, Control Units)

-

WAGNER (Powder Coating Guns, Automatic Systems, Recovery Systems)

-

Nordson Corporation (Powder Spray Guns, Booths, Recovery Systems)

-

Eastwood Company (DIY Powder Coating Guns, Ovens)

-

ANEST IWATA Corporation (Powder Spray Guns, Electrostatic Equipment)

-

Red Line Industries Ltd (Powder Coating Guns, Manual & Automatic Systems)

-

Carlisle (Electrostatic Powder Coating Systems, Spray Guns)

-

Pittsburgh Spray Equipment Co. (Powder Coating Guns, Booths, Accessories)

-

SAMES KREMLIN (Powder Coating Applicators, Automatic Guns)

-

Statfield Equipment Pvt. Ltd. (Powder Coating Systems, Guns, Ovens)

-

Hangzhou Color Powder Coating Equipment Co., Ltd. (Powder Coating Booths, Ovens, Guns)

-

Parker Ionics (Powder Coating Guns, Automatic & Manual Systems)

-

Gema Switzerland GmbH (Powder Coating Booths, Guns, Recovery Units)

-

Graco Inc. (Powder Spray Systems, Electrostatic Guns)

-

ITW Gema (Automatic & Manual Powder Coating Equipment)

-

Clemco Industries Corp. (Powder Coating Booths, Blast Cleaning Systems)

-

Kooltronix (Powder Coating Booth Cooling Systems)

-

Sames North America (Electrostatic Powder Coating Equipment, Guns)

-

Hillenbrand Inc. (Industrial Coating Systems, Powder Handling Equipment)

-

Xtrutech Ltd. (Powder Coating Extruders, Cooling & Cutting Systems)

Suppliers for (Innovative spray guns, painting systems, and complete powder coating solutions) on the Powder Coating Equipment Market

-

Nordson Corporation

-

Wagner Systems Inc.

-

Mitsuba Systems

-

Parker Ionics

-

Gema Switzerland GmbH

-

Sames

-

Golden Eagle

-

Hangzhou Color Powder Coating Equipment Co., Ltd.

-

Qingdao Coloreeze Eco-Protection Technologies Co., Ltd.

-

Hangzhou Kafan Machinery & Equipment Co., Ltd.

| Report Attributes | Details |

|---|---|

| Market Size in 2024 | USD 2.27 Billion |

| Market Size by 2032 | USD 3.11 Billion |

| CAGR | CAGR of 3.99% From 2025 to 2032 |

| Base Year | 2024 |

| Forecast Period | 2025-2032 |

| Historical Data | 2021-2023 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Product (Ovens & Booths, Powder Coat Guns, Others) • By Application (Consumer Goods, Architectural, Automotive, General Industries, Furniture, Others) |

| Regional Analysis/Coverage | North America (US, Canada), Europe (Germany, France, UK, Italy, Spain, Poland, Russsia, Rest of Europe), Asia Pacific (China, India, Japan, South Korea, Australia,ASEAN Countries, Rest of Asia Pacific), Middle East & Africa (UAE, Saudi Arabia, Qatar, Egypt, South Africa, Rest of Middle East & Africa), Latin America (Brazil, Argentina, Mexico, Colombia Rest of Latin America) |

| Company Profiles | Reliant Finishing Systems, Oven Empire Manufacturing, Mitsuba Systems Pvt. Ltd., WAGNER, Nordson Corporation, Eastwood Company, ANEST IWATA Corporation, Red Line Industries Ltd., Carlisle, Pittsburgh Spray Equipment Co., SAMES KREMLIN, Statfield Equipment Pvt. Ltd., Hangzhou Color Powder Coating Equipment Co., Ltd., Parker Ionics, Gema Switzerland GmbH, Graco Inc., ITW Gema, Clemco Industries Corp., Kooltronix, Sames North America. |