Machine Safety Market Report Scope & Overview:

To Get More Information on Machine Safety Market - Request Sample Report

The Machine Safety Market Size was valued at USD 5.23 Billion in 2023 and is now anticipated to grow to USD 8.43 Billion by 2032, displaying a compound annual growth rate (CAGR) of 5.45% during the forecast Period 2024-2032.

The Machine Safety Market is experiencing rapid growth, driven by increased attention to workplace safety regulations, technological advancements, and widespread adoption of automation across various industries. Machine safety solutions are critical for safeguarding workers and machinery, as they help prevent accidents, reduce operational downtime, and minimize associated costs. These solutions include a diverse array of products like safety sensors, controllers, interlock switches, and emergency stop devices, all designed to enhance safety protocols in industrial settings.

Key industries such as manufacturing, oil & gas, pharmaceuticals, automotive, and food & beverages are increasingly adopting machine safety measures to comply with stringent safety regulations. International standards organizations, such as the International Electrotechnical Commission (IEC) and the Occupational Safety and Health Administration (OSHA), have enforced strict guidelines, prompting companies to integrate sophisticated safety systems. The focus on compliance with these regulations is vital for ensuring smooth operations and avoiding legal penalties, making machine safety solutions indispensable. Emerging trends such as the integration of the Industrial Internet of Things (IIoT) and advanced robotics are shaping the future of the machine safety market. Real-time monitoring, predictive maintenance, and smart safety solutions are becoming more popular as companies seek ways to enhance efficiency and minimize risk. The rise of cloud computing and AI-driven technologies is also revolutionizing machine safety by offering improved system management and decision-making capabilities.

In a major industry development, ABB and Microsoft announced a partnership to bring generative AI into industrial digital solutions, aiming to enhance safety, productivity, and sustainability. Additionally, Honeywell recently acquired SCADAfence, a leader in OT and IoT cybersecurity solutions, further strengthening its cybersecurity offerings for monitoring large-scale industrial networks, thus improving the overall safety landscape.

MARKET DYNAMICS

DRIVERS

- Stringent regulatory frameworks are compelling industries to adopt advanced safety systems to comply with global safety standards such as OSHA and the EU Machinery Directive.

Stringent regulatory frameworks are a significant driving force behind the adoption of machine safety systems globally. Governments and regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) in the U.S. and the European Union’s Machinery Directive, mandate strict safety standards to protect workers in industrial environments. These regulations require industries to implement advanced safety technologies to reduce workplace accidents, ensure employee well-being, and maintain operational efficiency. Compliance with such standards is not optional; failure to meet these requirements can result in hefty fines, legal consequences, and reputational damage.

The regulatory landscape covers a wide range of safety aspects, including safeguarding workers from hazardous equipment, preventing machine-related accidents, and ensuring that emergency stops, safety sensors, and other protective measures are in place. For example, OSHA has established specific guidelines for machine guarding, lockout/tagout procedures, and other safety protocols, which industries must follow. Similarly, the EU Machinery Directive outlines the minimum health and safety requirements for machinery placed on the European market, compelling manufacturers to design equipment with built-in safety features. These regulatory demands are particularly important in high-risk industries such as manufacturing, automotive, and chemicals, where even minor safety oversights can lead to severe consequences. As a result, companies are increasingly investing in automated safety systems such as safety relays, controllers, and interlocks to ensure compliance, minimize risks, and avoid costly disruptions. In essence, strict regulatory frameworks are pushing businesses to prioritize safety, driving the growth of the machine safety market.

- Technological advancements, such as advanced sensors, real-time monitoring, and AI-powered safety systems, enhance machine performance monitoring and compliance with safety standards, driving significant growth in the machine safety market.

Technological advancements play a pivotal role in propelling the growth of the machine safety market. Innovations such as advanced sensors, real-time monitoring systems, and AI-powered safety solutions are transforming how companies approach safety in industrial environments. Advanced sensors are now capable of detecting potential hazards and malfunctions with high precision, enabling proactive interventions before accidents occur. These sensors can monitor variables such as temperature, pressure, and vibration, providing critical data that ensures machinery operates within safe parameters. Furthermore, real-time monitoring systems allow for continuous oversight of equipment performance, alerting operators to any anomalies that may indicate a safety risk. This capability not only enhances workplace safety but also optimizes operational efficiency by reducing downtime and maintenance costs. Additionally, the integration of artificial intelligence (AI) into machine safety systems is revolutionizing risk assessment and management. AI algorithms can analyze vast amounts of data to predict potential failures or safety breaches, enabling companies to implement preventive measures swiftly. This predictive approach to safety not only complies with regulatory standards but also fosters a culture of safety awareness among employees. The combination of these technologies enables businesses to maintain high safety standards while enhancing productivity and operational reliability. As industries increasingly recognize the importance of safeguarding their workforce, the demand for innovative machine safety technologies continues to rise, driving substantial growth in the market. This trend reflects a broader commitment to leveraging technology to create safer, more efficient workplaces across various sectors.

RESTRAIN

- The high initial investment required for comprehensive machine safety systems poses a significant financial challenge for small and medium-sized enterprises (SMEs), which may find it difficult to cover the costs of equipment, installation, and maintenance.

The implementation of comprehensive machine safety systems often involves significant initial investment, which can be a substantial barrier, especially for small and medium-sized enterprises (SMEs). These businesses frequently operate on tighter budgets and may find it challenging to allocate funds for safety equipment, installation, and ongoing maintenance. The costs associated with advanced safety technologies, such as sensors, safety relays, and monitoring systems, can quickly add up, placing a strain on the financial resources of SMEs. Additionally, the requirement for specialized installation and training can further escalate expenses, making it difficult for these companies to achieve compliance with safety regulations. While the long-term benefits of improved safety and reduced accident-related costs can outweigh the initial investment, the upfront financial burden can deter many SMEs from adopting necessary safety measures, potentially compromising worker safety and regulatory compliance in the process. This challenge underscores the need for affordable solutions and financial support for SMEs in the machine safety market.

KEY SEGMENTATION ANALYSIS

By Product Type

The Safety Sensors & Switches is dominated the market with a share of 32.12% in 2023. With the growth of industries and demand for safety sensors & switches has increased exponentially leading to making of dominating position in market. Safety sensors and switches are adopted at large across various production facilities and lines for minimizing safety intrusion during Robotic Process Automation (RPA) operation.

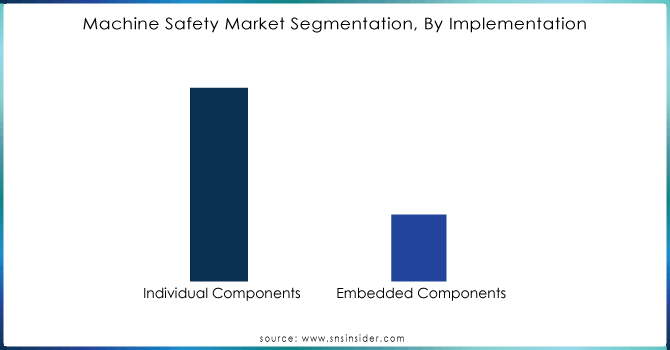

By Implementation

The Embedded Component is dominated the market with a share of 53.08% in 2023. Embedded components require integration of safety features into the control systems and design of machines. Safety functions are built-in embedded within control and automation architecture offering a streamlined safety solution, reducing the complexity of separate safety components.

Do You Need any Customization Research on Machine Safety Market - Inquire Now

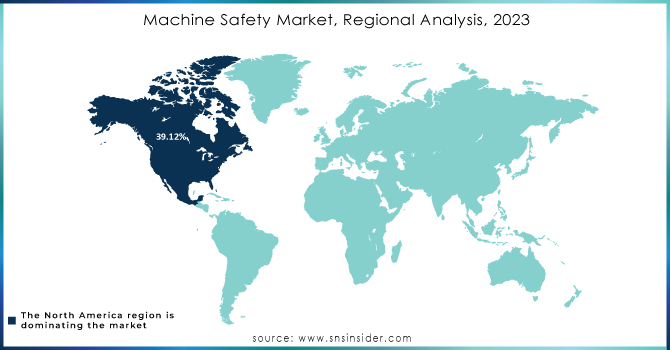

REGIONAL ANALYSIS

North America is currently dominating, holding a significant market share of 39.12%. This dominance is driven by stringent rules and regulations governing workplace safety. The region has seen a surge in the adoption of advanced automated technologies, coupled with a strong emphasis on worker safety. Continuous improvements in machine safety solutions are also contributing to North America’s leading position.

Europe is emerging as the fastest-growing region in the Machine Safety Market, outpacing North America. This growth is driven by the region's strict workplace safety regulations, compelling industries to adopt advanced safety systems. As compliance becomes a priority, the demand for innovative machine safety solutions is accelerating across various sectors. This regulatory push is positioning Europe for rapid market expansion.

KEY PLAYERS

Some of the major key players of Machine Safety Market

- ABB Ltd.:(Jokab Safety Devices)

- Banner Engineering: (Safety Light Curtains)

- Honeywell International Inc.: (Safety Interlock Switches)

- IDEC Corporation: (Safety Controllers)

- ISE Controls: (Safety Relay Modules)

- KEYENCE CORPORATION: (Safety Laser Scanners)

- Mitsubishi Electric Corporation: (Safety Programmable Controllers)

- OMRON Corporation: (Safety Mat Sensors)

- Pepperl+Fuchs: (Safety Sensors)

- Pilz GmbH & Co. KG: (PSEN Safety Gate Systems)

- Rockwell Automation Inc.: (Guardmaster Safety Relays)

- Schneider Electric: (Preventa Safety Controllers)

- SICK AG: (Safety Light Curtains)

- Siemens AG: (Safety Integrated Controllers)

- Emerson Electric Co.: (ASCO Safety Shutoff Valves)

- Euchner GmbH + Co. KG: (Safety Switches)

- TÜV Rheinland: (Functional Safety Services)

- Schmersal Group: (Safety Interlock Systems)

- Panasonic Corporation: (Safety Light Grids)

- Leuze Electronic GmbH + Co. KG: (Safety Laser Scanners)

RECENT DEVELOPMENTS

In June 2023: at the forefront of digitally transforming energy management and automation, Schneider Electric unveiled an updated edition of its primary Square D safety switch, the VisiPacT heavy-duty safety switch. This latest release introduces fresh functionalities and a revitalized design to enhance the reliability of the existing offering.

In January 2023: Siemens launched two new aspirating smoke detectors (ASD): FDA261 and FDA262. The biggest coverage area currently offered on the market is 6,700 m2, which can be covered by one smoke detector. A single ASD+ detector can provide up to 2,000 m2 of detection coverage, even for Class A installations with the strictest sensitivity requirements. With the new ASD Connect app, digital commissioning is quick and simple. It significantly automates and simplifies the commissioning procedure.

In August 2023: Yokogawa Electric Corporation will upgrade the Collaborative Information Server, part of the OpreX Control and Safety System, to enhance alarm management, access to maintenance data, and support international communication standards.

In April 2023: SICK sensor intelligence launched 3D Cameras with integrated time of flight technology. The technology comes with machine vision and a safety camera with programmability that protects the co-bots from collision.

In September 2023: Bollé Safety launched PPE accessory for cleanroom professionals. The product provides the use of sterilized eye protection to ensure operator safety and maintain reduced contamination levels.

In June 2023: Wabtec announced the launch of its Generation 3 Collision Avoidance System (CAS). The new system will enhance productivity and safety, as well as deliver a new level of performance with intelligence and rules capability.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 5.23 Billion |

| Market Size by 2032 | USD 8.43 Billion |

| CAGR | CAGR of 5.45% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • by Product Type (Presence-Sensing Safety Sensors, Emergency Stop Devices, Programmable Safety Systems, Safety sensors & switches, Safety Interlock Switches, Two-Hand Safety Controls, Others) • by Implementation(Individual Components, Embedded Components) • by End users(Oil & Gas, Energy & Power, Chemical, Food & Beverage, Aerospace & Defense, Automotive, Semiconductor & Electronics, Healthcare & Pharmaceutical, Metals & Mining, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | ABB, Banner Engineering, Honeywell International Inc, IDEC Corporation, ISE Controls, KEYENCE CORPORATION, Mitsubishi Electric Corporation, OMRON Corporation, Pepperl+Fuchs, Pilz GmbH & Co. KG, Rockwell Automation Inc., Schneider Electric, SICK AG, Siemens AG, Emerson Electric Co.Euchner GmbH + Co. KG, TÜV Rheinland, Schmersal Group, Panasonic Corporation, Leuze electronic GmbH + Co. KG |

| Key Drivers | • Stringent regulatory frameworks are compelling industries to adopt advanced safety systems to comply with global safety standards such as OSHA and the EU Machinery Directive. • Technological advancements, such as advanced sensors, real-time monitoring, and AI-powered safety systems, enhance machine performance monitoring and compliance with safety standards, driving significant growth in the machine safety market. |

| RESTRAINTS | •The high initial investment required for comprehensive machine safety systems poses a significant financial challenge for small and medium-sized enterprises (SMEs), which may find it difficult to cover the costs of equipment, installation, and maintenance. |