Mass Flow Controller Market Report Scope & Overview:

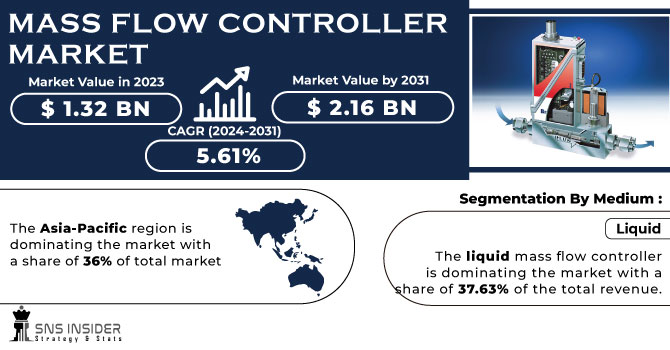

The Mass Flow Controller Market Size was valued at USD 1.32 Billion in 2023 and is now anticipated to grow USD 2.16 Billion by 2031, displaying a compound annual growth rate (CAGR) of 5.61% during the forecast Period 2024-2031.

The Mass Flow Controller Market is growing significantly because of mainly increasing demand for semiconductor sector and requirement in renewable energy applications, thus helping in the growth of market. These controllers are resilient to fluctuations in any way.

Get More Information on Mass Flow Controller Market - Request Sample Report

Also, with the increasing automation making even more precise and efficient operations making it a key driver in growth of market. The market is expected to benefit from several trends like ongoing growing demand for efficient energy solutions will likely drive the need for MFCs. Additionally, a focus on automation and process control across various industries is expected to further propel market growth. The mass flow controller mainly consists of sensor, inlet and outlet ports, and a control valve. Also, with increasing demand for water & wastewater treatment across various areas helping in the growth of market. These factors are creating a favorable market outlook across the globe in the coming future. These factors are creating a favorable market outlook across the globe in the coming future.

Mass Flow Controller Market Dynamics

Drivers

-

Increase in usage of mass flow controllers among semiconductor manufacturers

The mass flow controller is an essential component for the manufacturing of semiconductor leading to a growth driver for the market. The semiconductor industry has no substitute other than mass flow controller. Therefore, the constant demand for mass flow controllers in the semiconductor industry drives market growth.

-

Growth in demand for industrial automation in several developing countries throughout the globe.

Restraints

-

High initial cost and continuous calibration creates a restraint for growth of mass flow controllers.

-

Variation in differential pressure of MFCs can create a restraint in flow measurement.

Opportunities

-

Increase in use of mass flow controllers in space applications.

-

Machine integration With IoT and Industry 4.0 Technologies.

Challenges

-

Media dependency in calibration of mass flow controllers

Scheduled calibration is a necessary maintenance activity for mass flow controllers. This activity is used to ensure the reliable and efficient functioning of these controllers. The medium of mass flow controllers can be nitrogen, oxygen, helium, and many different gases or liquids.

-

Limited compatibility with different variety of Gases.

Impact of Russia-Ukraine War

The Russia-Ukraine war has a huge impact on mass flow controller (MFC) market. There have been disturbances in the supply chain caused. Russia and Ukraine are key exporters of raw materials required for MFC manufacturing but the war has led to shortages of raw materials resulting in price hikes. The supply chain disruption may have an indirect impact on demand. Industries like semiconductors, food & beverage which heavily rely on MFCs, may face a temporary reduction in demand of controllers. But the positive side is some countries may focus on manufacturing of MFC components leading to a market growth. Furthermore, some industries may see a reduction in demand while others like pharmaceuticals that use MFCs may see a rise due to war. by diversification of suppliers, inventory management and finding alternative materials used for the manufacturing of MFC can help in the solving the issues that arise due to war.

Impact of Economic Slowdown

Economic slowdown has a huge impact in the growth of mass flow controller market. Semiconductors and chemical industry heavily rely on MFCs for precise control of flow may have to cut back its production, which could lead to a decrease in demand for controllers. Companies may have to look for budget control, delaying purchasing of new MFCs. In order save costs companies may think of prioritizing repairs and maintenance of existing MFCs rather than buying new equipment’s. But there’s a positive side by usage. Even during slowdown, companies may prioritize keeping essential equipment like MFCs operational to avoid any disruptions in productions. Some may even see MFCs as a long-term investment, improving process efficiency and reducing waste are key factors during this economic slowdown. Furthermore, the demand for MFCs maintenance, calibration, and repairing may rise as companies try to extend the lifespan of existing controllers. The impact may depend on intensity and duration of slowdown. Companies that rely heavily on MFCs may perform periodic maintenance or even increase their usage. MFC manufacturers can adapt to this slowdown by improving cost-saving benefits, focusing more on after-sales services and also offering a wide range of controllers at various price points. The slowdown may bring a temporary halt in the growth of market, but in the long run the growth of mass flow controller market is significant.

KEY MARKET SEGMENTATION

By Medium

-

Gas

-

Liquid

-

Others

The liquid mass flow controller is dominating the market with a share of 37.63% of the total revenue. Liquid mass flow controller is dominating in food in the food and beverage industry in control of liquid flow in blending, mixing and bottling activities. So, with the growth of food and beverages industry has a consecutive effect on the growth of liquid segment.

By Industry

-

Semiconductors

-

oil & gas

-

Chemical

-

Pharmaceuticals

-

food & beverages

-

water & wastewater treatment

-

metals & mining

-

others

The semiconductor industry dominating the market with a share of 36% of the total revenue. Mass Flow Controllers helps in the regulation of flow rates of precursor gases like silane, ammonia and tungsten hexafluoride which are essential for depositing thin films onto silicon wafers. Mass flow controllers is a crucial equipment in the semiconductor industry, providing accurate and reliable control of gas flows essential for various manufacturing processes.

By Material

-

Stainless Steel

-

Exotic Alloys

-

Others

Regional Analysis

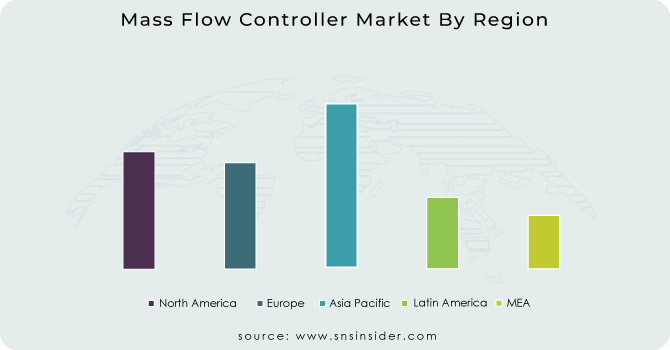

The Asia-Pacific region is dominating the market with a share of 36% of total market because growing semiconductor industry. Asia-Pacific being is one of the majority manufacturers of electronics devices like mobile phones, laptops, etc. and semiconductors are widely used in these types of devices. Following Asia-Pacific, North America is the fastest growing region.

Get Customized Report as per your Business Requirement - Request For Customized Report

Regional Outlook

North America

-

US

-

Canada

-

Mexico

Europe

-

Eastern Europe

-

Poland

-

Romania

-

Hungary

-

Turkey

-

Rest of Eastern Europe

-

-

Western Europe

-

Germany

-

France

-

UK

-

Italy

-

Spain

-

Netherlands

-

Switzerland

-

Austria

-

Rest of Western Europe

-

Asia Pacific

-

China

-

India

-

Japan

-

South Korea

-

Vietnam

-

Singapore

-

Australia

-

Rest of Asia Pacific

Middle East & Africa

- Middle East

-

UAE

-

Egypt

-

Saudi Arabia

-

Qatar

-

Rest of the Middle East

-

-

Africa

-

Nigeria

-

South Africa

-

Rest of Africa

-

Latin America

-

Brazil

-

Argentina

-

Colombia

-

Rest of Latin America

Key Players

The major key players are Bronkhorst, Brooks Instrument, MKS Instruments, Alicat Scientific, Sierra Instruments, Inc., Teledyne Hastings Instruments, Horiba, Sensirion AG, PARKER HANNIFIN CORP, Proterial Ltd, New Hills Pumping Inc and others.

Brooks Instrument-Company Financial Analysis

Mass Flow Controller Market Recent Developments

-

In January 2023 HORIBA India announced the establishment of a Semiconductor Mass Flow Controller (MFC) Repair and Calibration facility at the HORIBA India Technical Center in Pune.

-

In January 2024 Bronkhorst High-Tech B.V. expanded its gas flow meters and controllers' series by launching the MASS STREAM D-6400 Series Mass Flow Meter/Controller.

-

In September 2023 Brooks Instrument LLC launched a new line of Quantim QMC Coriolis mass flow controllers (MFCs), made to accurately measure very small amounts of liquids and gases.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | US$ 1.32 Billion |

| Market Size by 2031 | US$ 2.16 Billion |

| CAGR | CAGR of 5.61% From 2024 to 2031 |

| Base Year | 2023 |

| Forecast Period | 2024-2031 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Medium (Gas, Liquid, Others) • By Industry (Semiconductors, oil & gas, Chemical, Pharmaceuticals, food & beverages, water & wastewater treatment, metals & mining, others) • By Material (Stainless Steel, Exotic Alloys, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Bronkhorst, Brooks Instrument, MKS Instruments, Alicat Scientific, Sierra Instruments, Inc., Teledyne Hastings Instruments, Horiba, Sensirion AG, PARKER HANNIFIN CORP, Proterial Ltd, New Hills Pumping Inc |

| Key Drivers | • Increase in usage of mass flow controllers among semiconductor manufacturers • Growth in demand for industrial automation in several developing countries throughout the globe. |

| Challenges | • Media dependency in calibration of mass flow controllers • Limited compatibility with different variety of Gases. |