Metallic Stearates Market Report Scope & Overview:

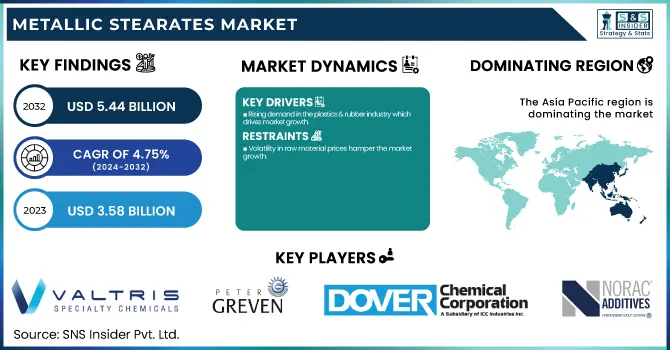

The Metallic Stearates Market size was USD 3.58 Billion in 2023 and is expected to reach USD 5.44 Billion by 2032 and grow at a CAGR of 4.75 % over the forecast period of 2024-2032. The metallic stearates market report provides a comprehensive analysis of production capacity and utilization by country and type, offering a detailed view of key manufacturing hubs. It examines feedstock prices and supply chain dynamics, highlighting raw material cost fluctuations and their impact on production. The report also explores regulatory impact and compliance, outlining country-specific regulations affecting various applications. Additionally, it covers environmental and sustainability metrics, focusing on emissions, waste management, and the shift toward bio-based alternatives. Furthermore, the study delves into innovation and R&D investments, showcasing advancements in high-purity and specialty metallic stearates. Lastly, it analyzes market adoption and application trends, identifying industry-specific demand patterns across plastics, rubber, pharmaceuticals, and coatings.

To Get more information on Metallic Stearates Market - Request Free Sample Report

Metallic Stearates Market Dynamics

Drivers

-

Rising demand in the plastics & rubber industry which drives market growth.

The metallic stearate market is strongly driven by the increasing demand from the plastics and rubber industry as these compounds are essential in processing and product performance. Metallic stearates are used as lubricants, release agents, and stabilizers in the production of plastics and rubbers. They enhance processing efficiency by avoiding the stickiness of the materials to molds and machinery, reducing friction, and improving dispersion in polymer formulations. Increasing product application in automotive components, Construction materials, and packaging solutions is driving metallic stearates in polyvinyl chloride (PVC), polyethylene, polypropylene, and synthetic rubber applications. Further, the growing use of lightweight, durable plastics in electric vehicles (EVs) and consumer goods is also expanding the market space. The growth of the automotive, construction, and packaging industries is anticipated to boost the demand for metallic stearates in the forthcoming years.

Restraint

-

Volatility in raw material prices hamper the market growth.

High price volatility in raw materials directly hampers the growth of the metallic stearates market as these compounds are predominantly manufactured with stearic acid and metal oxides such as zinc, calcium, magnesium, and aluminum. As stearic acid is mainly derived from animal fats and vegetable oils, the prices of these feedstocks are subject to fluctuations due to global supply chain disruptions, geopolitical tensions, and changes in crude oil prices. Price volatility in metal commodities due to mining regulations and trade policies has also contributed to higher production costs. However, the volatility makes it difficult for manufacturers to keep prices steady, which in turn hits their profit margins and makes them less competitive, especially small- and medium-sized enterprises SMEs. Such price volatility is reflected on downstream industries such as plastics, rubber, and pharmaceuticals disrupting the end-users' ability to forecast costs and streamline procurement effectively.

Opportunity

-

Growth in the paints & coatings industry creates an opportunity in the market.

There are lucrative opportunities in the metallic stearates market particularly in the paints and coatings industry due to its increasing application in the paints and coatings industry due to the rise in infrastructure development, urbanization, and increase in demand for high-performance coatings, especially in emerging economies. Metallic stearates are extensively employed as flatting agents, dispersants, and thickeners, particularly calcium and zinc stearates, to give the formulation texture, durability, and uniformity, to the coatings, respectively. Furthermore, the demand for metallic stearates is also being driven by the growing trend toward water-borne and eco-friendly coatings as metallic stearates are used to enhance surface properties or reduce gloss levels. However, due to constant R&D in sustainable and specialty coatings, manufacturers are working on broadening the scope of bio-based metallic stearates to eliminate the need for harsh solvents and meet stringent environmental regulations are some of the factors anticipated to create new growth avenues for the market.

Challenges

-

Manufacturing and quality control issues may create a challenge for the market.

Stringent performance and purity requirements from several industries may pose a challenge to the metallic stearates market, due to manufacturing and quality control issues. The metallic stearates used in manufacturing processes have to abide by stringent regulations to ensure they are safe, consistent, and free of contamination, especially in the pharmaceutical, food, and cosmetics sectors. Deviations in the quality of the raw material, processing conditions or data, or even formulation itself can cause non-compliance in the related industry regulations resulting in product recall or breakdown of its supply chain. Moreover, for the applications of plastics, rubber, and coatings, deviations in particle size, moisture content, and dispersion properties are incompatible with the mechanical and aesthetic properties the final product has to meet. Compounding that challenge are the disparate manufacturing technologies used to make biopharmaceuticals that need standardized global production guidelines.

Metallic Stearates Market Segmentation Analysis

By Product

The Zinc Stearate segment held the largest market share around 32% in 2023. It is the widely adopted type among other types in the market globally, major applications of zinc stearate are across industries such as plastics, rubber, paints & coatings, pharmaceuticals, and cosmetics, driving this segment in the metallic stearates market. Due to its unique lubricant, anti-caking, and release characteristics, it is an additive of choice in the production and processing of polymers with application as a mold release agent or to improve flow of material during plastic processing. Zinc stearate is widely used as a processing aid and release agent in the rubber industry, which is enhancing its dominance. It also acts as a very fruitful additive in paints & coatings due to its ability to repel water and stabilize, keeping pigments from clumping and increasing dispersion. Growth in the pharmaceutical and other cosmetics industries also stimulates demand for zinc stearate is used as a tablet lubricant and emulsifier.

By Application

Pharmaceuticals held the largest market share around 22% in 2023. It is owing to the vital function of metallic stearates, as excipients of the drug, in drug formulation. These compounds are popular, but also controversial, lubricants, anti–adherents, and flow agents used in the manufacture of tablets and/or capsules to facilitate smooth processing, prevent ingredients from binding to machinery, and create consistency within drugs. Rising demand for healthcare, the burgeoning of generic drug manufacturing, and increasing applications of biopharmaceuticals in the treatment of various diseases have been some of the other factors propelling the pharmaceutical industry, which in turn has significantly increased the consumption of metallic stearates. In response to the stringent regulatory standards of pharmaceutical manufacturing, several manufacturers are focusing on quality and compliance, as purity and quality pharmaceutical-grade metallic stearates are gaining momentum.

Metallic Stearates Market Regional Outlook

Asia Pacific held the largest market share around 42% in 2023. Metallic stearates are widely produced in countries such as China, India, Japan, and South Korea due to the availability of raw materials, a geographic advantage in lower production costs, and thriving end-use industries. The growing pharmaceutical and cosmetics industries in the region due to increasing healthcare spending and rising consumer demand for personal care products also contribute to boosting the market growth. Moreover, the growing automotive and construction sectors are expected to boost the consumption of metallic stearates in paints & coatings and polymer applications. Asia Pacific continues to lead the market owing to its growing government initiatives towards industrial growth and foreign direct investment in manufacturing. The region is also expected to sustain its dominance in the metallic stearates market owing to increasing urbanization, development of infrastructure, and increasing exports.

North America held a significant share. It is driven by high demand for quality excipients in drug manufacturing from the U.S. region, the consumption of pharmaceutical-grade metallic stearates such as magnesium and calcium stearate has been rampant in the region. Furthermore, the growth of the North American automotive and construction industries has boosted demand for metallic stearates due to their use in polymer processing, paints & coatings, and rubber applications. The leading chemical manufacturers will continue to drive product innovation and quality, especially in sustainable and bio-based metallic stearates backed by strict regulatory standards. In addition, the region's current emphasis on sustainable and premium materials has also resulted in research and development, adding to the overall growth of the marketplace. North America together with the rapidly changing industrial landscape and more and more specialty metallic stearates applications has partnered largely in the global market.'

Get Customized Report as per Your Business Requirement - Enquiry Now

Key Players

-

Baerlocher GmbH (Baerolub, Baerostab)

-

FACI Group (Faci Zinc Stearate, Faci Calcium Stearate)

-

Valtris Specialty Chemicals (Synpro Zinc Stearate, Synpro Calcium Stearate)

-

Peter Greven GmbH & Co. KG (LIGAMED MF-2-V, LIGASTAR ZN 101)

-

Dover Chemical Corporation (Doverlube, Doverguard)

-

Norac Additives (COAD 10, COAD 20)

-

Sun Ace Kakoh (Sunace Zinc Stearate, Sunace Calcium Stearate)

-

BELIKE Chemical (BELWAX ZN-65, BELWAX CA-62)

-

Tianjin Langhu Chem (LH-ZNST, LH-CST)

-

Seoul Fine Chemical (SFC Zinc Stearate, SFC Calcium Stearate)

-

Pratham Stearchem (Pratham Zinc Stearate, Pratham Calcium Stearate)

-

James M. Brown Ltd. (JMB Zinc Stearate, JMB Magnesium Stearate)

-

Shree Vallabh Chemicals (SVC Zinc Stearate, SVC Magnesium Stearate)

-

Peter Greven Asia (LIGAFOOD ZN-30, LIGASTAR MG 5000)

-

Baerlocher USA (Baeropan, Baerolub)

-

Evergreen Industries (Everlube Zinc Stearate, Everlube Calcium Stearate)

-

Hunan Shaoyang Tiantang Additives (TTA-ZS, TTA-CS)

-

Sigma-Aldrich (ReagentPlus Zinc Stearate, ReagentPlus Calcium Stearate)

-

IRRH Specialty Chemicals (IRRH ZN-ST, IRRH CA-ST)

-

DEUREX AG (DEUREX Z 67, DEUREX CA 65)

Recent Development:

-

In 2024, Bayer established a new R&D facility in Germany and is restructuring its organization to accelerate decision-making, strengthening its role as a leader in agrochemical innovation.

-

In 2024, FMC has broadened its portfolio with additional biological and digital solutions, focusing on enhancing crop productivity and sustainability.

| Report Attributes | Details |

| Market Size in 2023 | USD 3.58 Billion |

| Market Size by 2032 | USD 5.44 Billion |

| CAGR | CAGR of4.75% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | •By Product (Zinc Stearate, Calcium Stearate, Aluminum Stearate, Magnesium Stearate, Sodium Stearate, Lithium Stearate, Others) • By End-Use Industry (Plastics, Rubber, Pharmaceutical, Cosmetics, Building & Construction, Paints & Coatings, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Baerlocher GmbH, FACI Group, Valtris Specialty Chemicals, Peter Greven GmbH & Co. KG, Dover Chemical Corporation, Norac Additives, Sun Ace Kakoh, BELIKE Chemical, Tianjin Langhu Chem, Seoul Fine Chemical, Pratham Stearchem, James M. Brown Ltd., Shree Vallabh Chemicals, Peter Greven Asia, Baerlocher USA, Evergreen Industries, Hunan Shaoyang Tiantang Additives, Sigma-Aldrich, IRRH Specialty Chemicals, DEUREX AG |