Microchannel Heat Exchanger Market Report Scope & Overview:

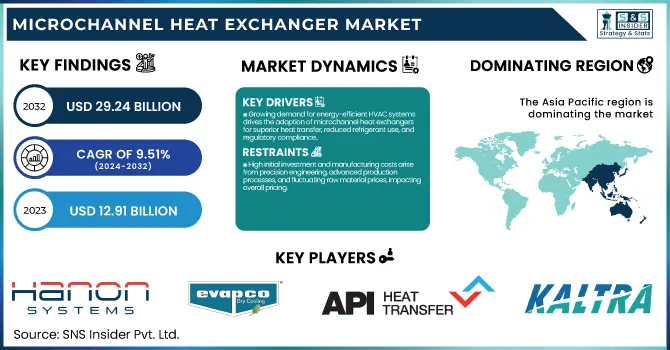

The Microchannel Heat Exchanger Market Size was estimated at USD 12.91 billion in 2023 and is expected to arrive at USD 29.24 billion by 2032 with a growing CAGR of 9.51% over the forecast period 2024-2032. The Microchannel Heat Exchanger Market is experiencing strong production growth, with Asia-Pacific leading due to rising demand in HVAC and automotive applications. Capacity utilization rates remain high in key regions, reflecting strong operational efficiency. The adoption of advanced coatings and corrosion-resistant materials is enhancing durability and performance. Maintenance-related disruptions have decreased, improving overall system reliability. Export-import trends indicate a significant shift, with China maintaining dominance in exports, while North America increases imports to meet demand.

To Get more information on Microchannel Heat Exchanger Market - Request Free Sample Report

Microchannel Heat Exchanger Market Dynamics

Drivers

-

The rising demand for energy-efficient HVAC systems is driving the adoption of microchannel heat exchangers due to their superior heat transfer, lower refrigerant use, and compliance with stringent energy regulations.

The growing demand for energy-efficient HVAC systems is a key driver of the microchannel heat exchanger market. Given the rising apprehensions surrounding energy usage and environmental sustainability, industries and consumers are moving toward advanced heat exchange solutions that improve efficiency and decrease operating expenses. Microchannel heat exchangers provide a high heat transfer rate, low refrigerant charge, and small footprint compared to traditional systems, making them promising for application in modern-day HVAC installations in residential, commercial, and industrial buildings. Global governments are also imposing stricter energy efficiency measures, a factor that is expected to further drive the adoption of such systems. Moreover, growth in smart buildings along with the green construction trend is expected to increase demand for HVAC systems that prevent energy wastage. The hydrocarbon refrigerant market is seeing rapid advancements in technological updates, with the rise of alternative materials used as refrigerants and corrosion-resistant components. Due to increasing urbanization and rising global industrialization, the microchannel heat exchanger market is poised for steady growth, especially with investments in sustainable infrastructure and climate control technologies.

Restraint

-

High initial investment and manufacturing costs arise from precision engineering, advanced production processes, and fluctuating raw material prices, impacting overall pricing.

The high initial investment and manufacturing costs in the microchannel heat exchanger market stem from the advanced production processes and the use of high-quality materials like aluminum alloys. The high initial investment and manufacturing costs in the microchannel heat exchanger market arise from the advanced production processes and high-quality materials such as aluminum alloys. Unlike traditional heat exchangers microchannel technology demands precision engineer, specialized equipment, and automated production techniques to achieve high density, and high thermal efficiency, and compact design demands the best durability. Capital expenditure also includes the costs of setting up dedicated manufacturing facilities for extrusion, brazing, and coating processes. In addition, raw material costs (especially aluminum) are subject to huge fluctuations due to supply constraints in the chain and global market trends, impacting overall pricing. Investing in research and development (R&D) to improve corrosion resistance and enhance refrigerant flow contributes further to these high costs. These factors combined make microchannel heat exchangers expensive at first, compared with their traditional counterparts. This may restrict their adoption in cost-sensitive markets. However, long-term savings in running costs through improving energy efficiency and using less refrigerant can help offset these initial expenses over time.

Opportunities

-

The expansion of cold chain logistics in the food & beverage and pharmaceutical industries is driving demand for efficient, compact, and energy-saving microchannel heat exchangers.

The expansion of cold chain logistics is driving significant demand for refrigeration solutions, boosting the adoption of microchannel heat exchangers. The expansion of cold chain logistics is driving significant demand for refrigeration solutions, boosting the adoption of microchannel heat exchangers. For the food beverage industry, temperature-controlled storage and transport are a must to keep product freshness and safety assured. In the pharmaceutical industry, however, meticulous cooling solutions must be provided for vaccines, biologics, and any other temperature-sensitive drugs whatever their medium of administration. Demand for cost-efficient refrigerator systems has been further accelerated by the worldwide development of e-commerce grocery delivery services in recent years. On the other hand, the pharmaceutical industry's requirements for product integrity call for advancement in cooling technology. As a result, of highly efficient thermal efficiency, microchannel heat exchangers with compact designs become the best choice for modern refrigeration systems. When the demand for eco-friendly and cost-efficient refrigeration systems sustainable development is increasing, growth continues in the microchannel heat exchanger market.

Challenges

-

The Microchannel Heat Exchanger Market is highly competitive, driven by established players, emerging technologies, price pressures, and a strong focus on innovation and efficiency.

The Microchannel Heat Exchanger Market is highly competitive, driven by the presence of established global players and the continuous emergence of new technologies. The top manufacturers are concentrating on product innovation, material advances, and more efficiency to keep their footing in this tough battle for market share. Ancillary enterprises invest in R&D projects to extend the life of their products, solve corrosion problems, and improve thermal performance. They are adapting themselves to the changing needs of industries like HVAC (heating-ventilation-air conditioning) and car assembly and refrigerator manufacture. Meanwhile, the market is seeing the entrance of new players peddling economical and bespoke solutions, intensifying competition. The development of other types of heat exchangers, such as plate type or fin tube, also hamper market growth as they take a chunk out of the micro heat exchanger's market share. Prices are down and upward trends in raw material costs continue to impact the competitive landscape. Enterprises in the vanguard of prosperity are there because of strategic alliances, mergers by acquisition, as well as geographical expansion with new branches staffed according to local needs.

Microchannel Heat Exchanger Market Segmentation Analysis

By Type

The condenser segment dominated with a market share of over 46% in 2023, due to its crucial role in heat dissipation. Condensers effectively transfer heat from the refrigerant gases or working fluids to their surroundings meaning that HVAC and refrigeration systems are kept cool. They enjoy a reputation as the first choice in all sectors of industry with compact design, good heat transfer characteristics, and less refrigerant charge. Growing demand for energy-efficient cooling solutions for residential, commercial, and industrial applications further fuels its popularity. Also, advances in microchannel technology can promote performance, reduce system costs, and contribute to sustainability by saving energy. The condenser's significance in improving efficiency as climate designs evolve and reducing environmental impact continues to underscore its market leadership.

By Application

The HVAC segment dominated with a market share of over 48% in 2023, due to the growing demand for energy-efficient and compact cooling solutions. Microchannel heat exchangers excel at transferring heat, use less refrigerant, and simply perform better all around which makes them perfect for modern HVAC applications. Compared to other high-performance cooling industries the countryway is lighter and items also have a thermal efficiency which is relatively higher, helping to cut down on energy usage in line with worldwide sustainability goals. Watching cities filling up, stricter environmental regulations as well as progress in cooling technology, HVAC systems increasingly rely on microchannel heat exchangers to improve efficiency and reduce cost. Moreover, the emerging construction of commercial and residential buildings is providing further impetus to market development not only making HVAC the leading application for these products but also accelerating their growth.

Microchannel Heat Exchanger Market Regional Outlook

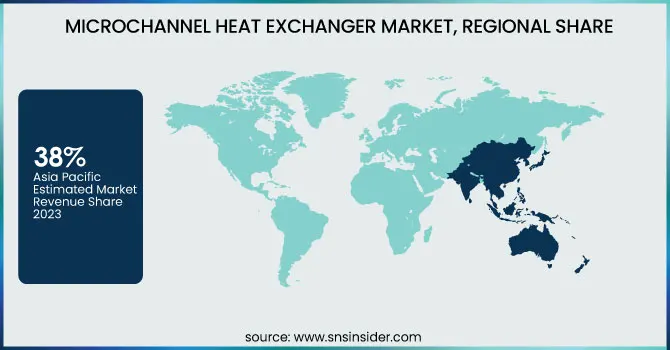

The Asia-Pacific region dominated with a market share of over 38% in 2023, primarily because swift industrialization brought expansion to major industries such as heating, ventilation, air conditioning, and automotive as well as electricity generation equipment. In particular large countries such as China, Japan, and India all have an impact on market growth: they benefit from lower costs in labor and technological expertise which offer these huge production facilities very favorable conditions to operate their projects so that they can be adopted quickly by users at home or abroad. The rising emphasis on energy-efficient refrigeration solutions and the extensive use of environmentally friendly coolants by consumers also drive market demand. Furthermore, the region's boom in construction and rapid urbanization continue to increase demand for microchannel heat exchangers in residential building projects and other construction. With strong government backing for sustainable energy solutions, Asia-Pacific is still the leader in the global market offering cost-effective yet high-performance cooling systems.

North America is emerging as the fastest-growing market for microchannel heat exchangers due to the increasing adoption of energy-efficient HVAC systems. Strict environmental regulations, such as those laid down by the U.S. Environmental Protection Agency and the U.S. Department of Energy, are driving demand for environmentally friendly and high-performance cooling solutions. This is coupled with the fact that automobile and aerospace heat exchangers need to be lighter weight, and more compact. In the U.S. but also abroad like in Europe as well. Its strong emphasis on sustainability and advanced technologies in coming years will also lift the market further: There will be improved corrosion resistance with longer life times for--. Performance It performs further modernization of heat exchanger technology, which is reflected by better thermal performance, and more corrosion-resistant materials. Thanks to investment in smart buildings, green technologies, and the like, North America continues to witness big-time growth in the microchannel heat exchanger market.

Get Customized Report as per Your Business Requirement - Enquiry Now

Some of the major key players in the Microchannel Heat Exchanger Market

-

Hanon Systems (Automotive HVAC, Battery Cooling Systems)

-

EVAPCO (Microchannel Condensers, Evaporators)

-

Climetal S.L (HVAC Coils, Refrigeration Heat Exchangers)

-

API Heat Transfer (Industrial Microchannel Heat Exchangers)

-

Sanhua International Europe S.L (Refrigeration Coils, Heat Pump Components)

-

Modine Manufacturing Company (Radiators, HVAC Coils)

-

Kaltra Innovativtechnik GmbH (Microchannel Condensers, Chiller Coils)

-

Goldstone HVACR Inc. (Microchannel Air Conditioning Coils)

-

Danfoss Group (Heat Exchanger Components, Refrigeration Solutions)

-

Alfa Laval (Industrial Cooling, HVAC-R Solutions)

-

Carrier Corporation (HVAC Microchannel Coils)

-

Sermeta (Gas Boiler Heat Exchangers)

-

Klein Wärmebehandlung GmbH (Industrial Heat Exchangers)

-

Mitsubishi Heavy Industries (Heat Pumps, Refrigeration Coils)

-

Daikin Industries Ltd. (Microchannel Coils for Air Conditioning)

-

Kelvion Holding GmbH (Industrial and Automotive Heat Exchangers)

-

Shanghai Shenglin M&E Technology Co., Ltd. (Refrigeration and HVAC Coils)

-

Zhejiang DunAn Artificial Environment Co., Ltd. (Refrigeration and Heat Pump Coils)

-

Modular Heat Exchangers Pvt. Ltd. (Compact Heat Exchangers)

-

Tata Advanced Systems (Aerospace and Automotive Cooling Systems)

Suppliers for (Provides customized solutions for refrigeration and HVAC industries) on Microchannel Heat Exchanger Market

-

Shanghai Shenglin M&E Technology Co., Ltd.

-

Alecoil

-

Venttech

-

Changzhou Vrcoolertech Refrigeration Co., Ltd.

-

Kaltra

-

Zhejiang SunCo Heat Exchange System Co., Ltd.

-

Modine Manufacturing Company

-

Danfoss

-

Sanhua

-

API Heat Transfer

Recent Development

-

In April 2023: Danfoss expanded its Z-design range of microchannel heat exchangers by introducing the C262L-EZD, a dual-circuit evaporator designed for roll-on coolers. These robust and reliable units enhance the product line’s capacity, offering cooling capabilities of up to 300 kW in a single circuit and up to 800 kW in two circuits.

-

In August 2023: Kaltra shortened the manufacturing time for microchannel heat exchangers by 30% following the completion of its production facilities, which included the installation of two new CAB furnaces and large indexing grids.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 12.91 Billion |

| Market Size by 2032 | USD 29.24 Billion |

| CAGR | CAGR of 9.51% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Type (Evaporator, Condenser, Water Coil) • By Application (HVAC (Air Conditioning, Heat Pump, Heat Pump Water Heater, Others), Automotive, Refrigeration, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Hanon Systems, EVAPCO, Climetal S.L, API Heat Transfer, Sanhua International Europe S.L, Modine Manufacturing Company, Kaltra Innovativtechnik GmbH, Goldstone HVACR Inc., Danfoss Group, Alfa Laval, Carrier Corporation, Sermeta, Klein Wärmebehandlung GmbH, Mitsubishi Heavy Industries, Daikin Industries Ltd., Kelvion Holding GmbH, Shanghai Shenglin M&E Technology Co., Ltd., Zhejiang DunAn Artificial Environment Co., Ltd., Modular Heat Exchangers Pvt. Ltd., Tata Advanced Systems. |