Packaging Adhesives Market Report Scope & Overview:

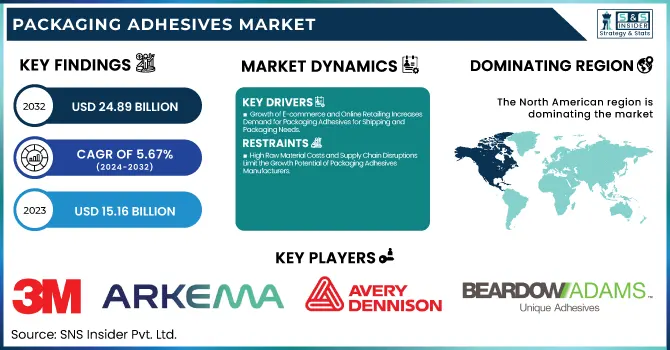

The Packaging Adhesives Market Size was valued at USD 15.16 Billion in 2023 and is expected to reach USD 24.89 Billion by 2032, growing at a CAGR of 5.67% over the forecast period of 2024-2032.

To Get more information on Packaging Adhesives Market - Request Free Sample Report

The Packaging Adhesives Market is evolving rapidly, shaped by innovation, sustainability, and shifting industry needs. Investment and funding trends reveal increased capital in research and development, driving eco-friendly adhesive solutions. Raw material analysis uncovers volatility in polymer and resin costs, affecting pricing and supply chains. A thorough cost structure and profitability analysis examines production expenses and market feasibility. Customer demographics and end-user preferences play a crucial role, with industries like food, pharmaceuticals, and e-commerce demanding specialized adhesives. Meanwhile, private label and small-scale manufacturers are gaining traction, offering competitive and customized solutions. Our report explores these key dynamics, offering deep insights into opportunities, challenges, and the future outlook of the packaging adhesives industry.

The US Packaging Adhesives Market Size was valued at USD 3.80 Billion in 2023 and is expected to reach USD 6.01 Billion by 2032, growing at a CAGR of 5.23% over the forecast period of 2024-2032. The U.S. Packaging Adhesives Market is experiencing steady growth, driven by advancements in sustainable packaging, increasing e-commerce activities, and stringent FDA regulations on food-safe adhesives. The Flexible Packaging Association (FPA) reports rising demand for flexible and lightweight packaging, boosting the need for high-performance adhesives. Additionally, companies like H.B. Fuller and Avery Dennison are investing in bio-based and recyclable adhesives to meet sustainability goals. Growth in the pharmaceutical and food industries, supported by the American Chemistry Council (ACC), further accelerates innovation in solvent-free and low-VOC adhesives. Our report explores these market dynamics, key players, and regulatory influences shaping the industry.

Packaging Adhesives Market Dynamics

Drivers

-

Growth of E-commerce and Online Retailing Increases Demand for Packaging Adhesives for Shipping and Packaging Needs

The exponential growth of e-commerce and online retailing has created new opportunities for the Packaging Adhesives Market. As consumer preferences shift towards online shopping, there is an increasing need for protective packaging to ensure the safe delivery of goods. Packaging adhesives play a crucial role in this process, especially in packaging for shipping and product protection. With Amazon and other major e-commerce players expanding their operations in the U.S., packaging solutions that offer both durability and cost-effectiveness have become essential. E-commerce companies are increasingly turning to adhesives for sealing packages, ensuring that products remain intact during transit. The growing adoption of flexible and corrugated packaging, commonly used in the e-commerce sector, is contributing to the increased demand for high-performance adhesives that can withstand handling, stacking, and shipping conditions. The Packaging Adhesives Market is benefiting from innovations in adhesives that offer faster curing times, better adhesion strength, and reduced waste, making them ideal for e-commerce packaging. This growing sector presents a significant opportunity for manufacturers to innovate and meet the unique packaging needs of online retailers.

Restraints

-

High Raw Material Costs and Supply Chain Disruptions Limit the Growth Potential of Packaging Adhesives Manufacturers

High raw material costs and supply chain disruptions present significant challenges to the growth of the Packaging Adhesives Market. The prices of key raw materials like resins, polymers, and solvents have been volatile, largely due to global supply chain issues and the limited availability of raw materials. These disruptions, exacerbated by geopolitical tensions and the COVID-19 pandemic, have impacted manufacturers' ability to maintain consistent production schedules and control costs. For instance, companies relying on imported raw materials are facing delays, leading to increased production costs. These challenges hinder the market's growth potential, especially for small and medium-sized manufacturers who are less equipped to absorb these cost increases. As a result, adhesive manufacturers are seeking alternative solutions, such as sourcing local materials and investing in technology to streamline production processes. However, these adjustments require significant investment, which could delay the widespread adoption of innovative packaging adhesives in the market.

Opportunities

-

Rising Demand for Lightweight and Flexible Packaging Drives Innovation in Adhesives for Sustainable Solutions

The growing demand for lightweight and flexible packaging solutions offers substantial opportunities for the Packaging Adhesives Market. As consumer preference shifts toward convenience, brands are adopting packaging formats that are not only lightweight but also more adaptable to various product types. Flexible packaging, which is often made from multi-layered materials, is gaining popularity due to its ability to preserve product freshness and reduce transportation costs. This trend has led to an increased demand for packaging adhesives that provide strong bonding while maintaining flexibility. Companies like Sika and Wacker Chemie are investing in the development of adhesives that are both lightweight and sustainable, meeting the growing need for flexible packaging in industries such as food, pharmaceuticals, and personal care. The rise of eco-friendly flexible packaging solutions further emphasizes the need for innovative adhesive technologies that can meet sustainability goals while offering the necessary performance characteristics. This trend is expected to continue driving opportunities for adhesive manufacturers to expand their product offerings.

Challenge

-

Intense Competition from Small-Scale Manufacturers and Private Labels Hinders Pricing and Market Share for Large Companies

The Packaging Adhesives Market is facing heightened competition from small-scale manufacturers and private label producers, which is creating pricing pressures for large companies. Smaller manufacturers are often able to offer competitive pricing, especially in niche markets, by leveraging cost-effective production methods and offering specialized adhesive formulations. These small-scale producers are increasingly gaining market share by targeting local and regional customers who prefer more affordable, customized solutions. As a result, large companies in the packaging adhesives sector are finding it challenging to maintain their dominant market position, particularly in price-sensitive markets. To combat this challenge, major players such as 3M and H.B. Fuller are focusing on product differentiation, investing in research and development to create high-performance adhesives that can command premium pricing. However, the pressure from private labels and smaller manufacturers is expected to intensify, particularly as consumers continue to demand more cost-effective, eco-friendly packaging solutions.

Packaging Adhesives Market Segmental Analysis

By Resin

Polyvinyl Chloride (PVC) resins dominated the Packaging Adhesives Market in 2023, with a market share of 28.6%. PVC adhesives are known for their excellent bonding properties and high durability, making them ideal for packaging applications in industries such as food and beverage, pharmaceuticals, and consumer goods. PVC adhesives offer robust resistance to environmental factors, providing strong bonds even in challenging conditions. The increasing demand for rigid packaging, especially bottles and containers, has contributed to the surge in PVC's usage. Companies like 3M and H.B. Fuller are continuously innovating to produce PVC-based adhesives that ensure optimal performance while reducing environmental impact. The rise in consumer demand for longer shelf-life products and the growing trend of lightweight, cost-effective packaging solutions further solidify PVC’s leading position in the market. Additionally, regulatory frameworks advocating for recyclable and reusable packaging have supported PVC’s adoption in packaging adhesives. The expansion of the packaging industry across emerging economies has also fueled the market for PVC resins, making it a dominant force in 2023.

By Technology

Water-based adhesives dominated the Packaging Adhesives Market in 2023, with a market share of 41.2%. The significant growth of water-based adhesives can be attributed to their environmentally friendly attributes, as they do not contain harmful solvents or volatile organic compounds (VOCs), aligning with stricter environmental regulations. The shift towards water-based technology is driven by the increasing consumer preference for sustainable products and the pressure from regulatory agencies such as the Environmental Protection Agency (EPA) to reduce emissions from packaging materials. Water-based adhesives are highly effective in a variety of packaging applications, including food and beverage packaging, where health and safety standards are critical. Major companies like Henkel and BASF have developed advanced formulations of water-based adhesives that offer superior performance, such as fast-drying and strong bonding capabilities, without compromising environmental responsibility. The rising focus on sustainable packaging solutions and eco-friendly products is expected to propel water-based adhesives to greater market share in the coming years. Moreover, government initiatives encouraging the reduction of plastic waste and promoting the use of water-based adhesives play a significant role in this technology’s dominance.

By Application

Flexible packaging dominated the Packaging Adhesives Market in 2023, accounting for 27.8% of the market share. The flexibility, cost-effectiveness, and convenience offered by flexible packaging solutions have led to their widespread adoption, particularly in the food, beverage, and pharmaceutical industries. Flexible packaging materials are lightweight, customizable, and provide excellent barrier protection against moisture, oxygen, and contaminants, making them ideal for preserving the freshness and quality of products. Leading packaging companies like Amcor and Sealed Air have significantly expanded their portfolios in flexible packaging, pushing the demand for adhesives that enhance the performance and sustainability of these materials. The growing consumer preference for convenient and eco-friendly packaging solutions has further fueled the rise of flexible packaging. Moreover, flexible packaging plays a key role in reducing material waste, offering manufacturers an environmentally responsible option. The Flexible Packaging Association highlights the industry’s shift toward more sustainable materials and adhesives, which is in line with governmental policies and consumer demand for environmentally conscious products. This combination of convenience, performance, and sustainability has ensured that flexible packaging remains the dominant segment in 2023.

Packaging Adhesives Market Regional Outlook

The North American region dominated the Packaging Adhesives Market in 2023, accounting for an estimated market share of 37.8%. This dominance can be attributed to the region's strong consumer demand for sustainable and high-performance packaging solutions, particularly within the food and beverage, healthcare, and consumer goods industries. The United States stands out as the largest contributor in this region, driven by the presence of key players like 3M, H.B. Fuller, and Dow Inc., which continue to innovate in developing environmentally friendly adhesives for diverse packaging needs. For instance, in the food sector, the demand for flexible packaging with high barrier properties has spurred the growth of packaging adhesives. Furthermore, the United States is home to stringent environmental regulations, such as the Environmental Protection Agency (EPA) standards, which have encouraged the adoption of water-based and solvent-free adhesives. Canada follows as a strong player, with rising investments in sustainable packaging technologies. Mexico also plays a significant role, due to its growing packaging industry and proximity to major manufacturers in the region. Together, these factors ensure North America's continued dominance in the Packaging Adhesives Market in 2023.

Moreover, the Asia Pacific region emerged as the fastest-growing region in the Packaging Adhesives Market during the forecast period, with a significant CAGR. This rapid growth can be attributed to the region's expanding industrial base, increasing population, and the rising demand for packaged goods, particularly in emerging economies like China, India, and Indonesia. In China, the largest packaging market in the region, demand for packaging adhesives is driven by sectors such as food and beverage, pharmaceuticals, and e-commerce. The government's focus on sustainability and the implementation of stricter environmental regulations have bolstered the adoption of eco-friendly adhesives. In India, rapid urbanization, increasing disposable income, and a growing middle class are propelling the packaging industry, further boosting the demand for adhesives. Japan, known for its advanced packaging solutions, continues to focus on innovative technologies and high-quality adhesives for a variety of industries. With these countries pushing towards sustainability and increased consumption of packaged goods, the Asia Pacific region is expected to continue leading the market's growth during the forecast period.

Get Customized Report as per Your Business Requirement - Enquiry Now

Key Players

-

3M Company (3M Hot Melt Adhesive 3762, 3M Scotch-Weld Hot Melt Adhesive 3748, 3M Adhesive 100MP)

-

Arkema S.A. (Bostik) (Bostik 1000, Bostik Glue Dots, Bostik M1000)

-

Avery Dennison Corporation (Fasson S692N, Fasson S2000N, Fasson S2045)

-

Beardow Adams (BAMFutura 1, BAMFutura 3, BAMFutura 51)

-

DIC Corporation (DICDRY LQ-3600, DICSEAL SB-2000, DICDRY LQ-3300)

-

Dow Inc. (The Dow Chemical Company) (DOWSIL 732 Multi-Purpose Sealant, DOWSIL 256 Structural Adhesive, DOWSIL 2020 Adhesive)

-

Evonik Industries AG (TEGO® RC 100, TEGO® RC 110, VESTAMELT 1030)

-

Franklin International (Titebond III, Titebond II Premium, Titebond Original)

-

H.B. Fuller Company (Advantra 9280, SwiftTak 5730, Fuller 1280)

-

Henkel AG & Co. KGaA (Technomelt Supra 100, Technomelt Supra 300, Aquence PS 3017)

-

ITW Performance Polymers (Illinois Tool Works Inc.) (Plexus MA310, Plexus MA300, Devcon 5 Minute Epoxy)

-

Jowat SE (Jowatherm 245.00, Jowatherm 250.00, Jowacoll 103.10)

-

Paramelt RMC B.V. (Paraflex M, Paraflex A, Paraflex R)

-

Sika AG (Sikaflex-221, Sikaflex-265, SikaBond T-8)

-

Toyochem Co., Ltd. (Oribain EXK-3, Oribain EXK-5, Oribain EXK-7)

-

Wacker Chemie AG (VINNAPAS EP 7000, VINNAPAS EP 8000, VINNAPAS EP 8010)

-

Wisdom Adhesives Worldwide (Wisdom Hot Melt Adhesive, Wisdom Water-Based Adhesive, Wisdom Pressure-Sensitive Adhesive)

-

Hexion Inc. (EPIKURE Curing Agent 8530, EPIKURE Curing Agent 8540, EPIKURE Curing Agent 8535)

-

Mitsui Chemicals, Inc. (TAFMER XM-7070, TAFMER XM-7080, TAFMER XM-7090)

-

Sun Chemical (a member of DIC Group) (SunLam SFC100, SunLam SFC200, SunLam SFC300)

Recent Developments

-

December 2024: Arkema finalized its acquisition of Dow’s flexible packaging laminating adhesives business for $150 million. The acquisition includes sites in Italy, the U.S., and Mexico, expanding Arkema’s adhesive portfolio and strengthening its specialty materials business.

-

December 2024: Dow completed the $150 million sale of its flexible packaging laminating adhesives business to Arkema. The transaction includes five production sites and aligns with Dow’s focus on high-value markets and sustainability goals, with proceeds reinvested into growth initiatives.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 15.16 Billion |

| Market Size by 2032 | USD 24.89 Billion |

| CAGR | CAGR of 5.67% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | •By Resin (Polyvinyl Alcohol (PVA), Acrylics, Polyvinyl chloride (PVC), Polyurethane, Others) •By Technology (Water Based, Solvent Based, Hot Melt, Others) •By Application (Case & Carton, Corrugated Packaging, Labeling, Flexible Packaging, Folding Cartons, Specialty Packaging, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Henkel AG & Co. KGaA, 3M Company, H.B. Fuller Company, The Dow Chemical Company (Dow Inc.), Arkema S.A. (Bostik), Avery Dennison Corporation, Sika AG, Wacker Chemie AG, DIC Corporation, Ashland Inc. and other key players |