Plate and Frame Heat Exchanger Market Report Scope & Overview:

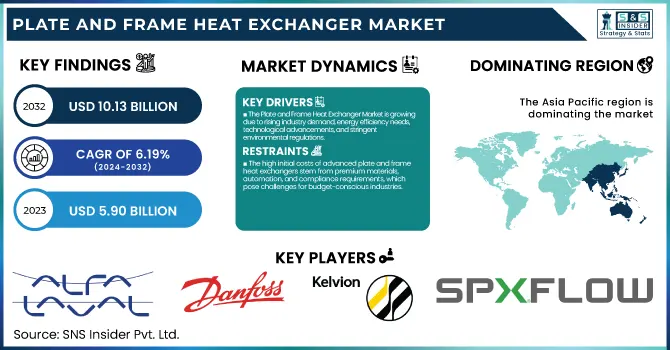

The Plate and Frame Heat Exchanger Market Size was esteemed at USD 5.90 billion in 2023 and is supposed to arrive at USD 10.13 billion by 2032 with a growing CAGR of 6.19% over the forecast period 2024-2032. The Plate and Frame Heat Exchanger Market report offers unique insights by analyzing manufacturing output trends across key regions, highlighting capacity utilization rates and efficiency benchmarks. It examines maintenance and downtime metrics, shedding light on operational reliability. The study also tracks technological adoption rates, emphasizing advancements in materials and automation. Additionally, it provides export/import trade data, mapping global supply chain shifts. Emerging trends include the rise of energy-efficient plate designs, increasing integration of IoT for real-time monitoring, and a growing focus on sustainable refrigerants in compliance with environmental regulations.

To Get more information on Plate and Frame Heat Exchanger Market - Request Free Sample Report

Plate and Frame Heat Exchanger Market Dynamics

Drivers

-

The Plate and Frame Heat Exchanger Market is growing due to rising industry demand, energy efficiency needs, technological advancements, and stringent environmental regulations.

The Plate and Frame Heat Exchanger Market is experiencing steady growth due to its increasing adoption across industries such as HVAC, chemical processing, power generation, and food & beverage. They require effective heat transfer solutions to maximize energy saving, optimize thermal management, and increase operational efficiency in these sectors. One of the major factors fueling the growth of the market is the increasing need for compact, high-performance, and cost-effective heat exchangers, especially in sustainable and energy-efficient industries. Moreover, technological advancements such as IIoT-enabled smart monitoring systems and the use of corrosion-resistant materials are enhancing the durability as well as the efficiency of these systems. Current industry trends point toward customizable and modular designs that fit the needs of a range of industries. Rest, strict environmental regulations encourage the use of eco-friendly refrigerants & energy-efficient equipment, which in turn leads to the growth of HVAC manufacturers. As the emerging markets industrialize fast the market for plate and frame heat exchangers is forecasted to reach a relatively high number in the next few years.

Restraint

-

The high initial costs of advanced plate and frame heat exchangers stem from premium materials, automation, and compliance requirements, which pose challenges for budget-conscious industries.

The high initial costs of advanced plate and frame heat exchangers pose a significant challenge for market adoption, particularly for small and mid-sized enterprises. With state-of-the-art materials including stainless steel, titanium, and special alloys for better thermal performance, corrosion resistance, and durability, these systems can do loads more work while requiring less maintenance. However using such high-quality materials raises manufacturing costs. Moreover, the advancement of automation, such as IIoT-enabled monitoring systems for predictive maintenance, further increases the initial cost. These advanced features do enhance operational efficiency over the long term and decrease maintenance costs, however, their initial capital expense tends to be a disincentive for industries with limited budgets. Before investing, companies frequently consider the balance between increased acquisition costs and long-term energy savings. Additionally, costs associated with installation, the need for customization, and adherence to strict industry regulations further exacerbate the financial burden. Thus, market penetration in price-sensitive regions and industries continues to be a major hurdle although the benefits of the technology are long-term.

Opportunities

-

Advanced thermal fluids improve heat exchanger efficiency by enhancing heat transfer, reducing energy use, and ensuring environmental compliance.

Advancements in heat transfer fluids are playing a crucial role in enhancing the efficiency of plate and frame heat exchangers. With thermal conductivity, stability, and lower viscosity, High-performance thermal fluids enable more efficient heating and cooling rates, which helps save energy and overall operational costs. New technologies like nanofluids, phase-change materials, and eco-friendly refrigerants are delivering performance enhancements across many sectors, from HVAC and power generation to chemical processing. The use of these sophisticated fluids ensures improved heat transfer, reduced fouling, and enhanced heat exchangers' longevity. Moreover, the trend toward the use of non-toxic, biodegradable, and low-GWP (Global Warming Potential) fluids complies with increasing environmental regulations; thus, these fluids have become a preferred option for sustainable industrial operations. Therefore, as societies strive for higher efficiency and reliability in these systems, the development of more efficient and sustainable tools for the design of advanced heat transfer fluids will likely improve heat exchanger performance across various industries, assisting energy conservation and contributing to global carbon footprint reduction.

Challenges

-

Retrofitting modern plate and frame heat exchangers into older industrial systems is challenging due to legacy infrastructure, space constraints, compatibility issues, and costly modifications.

Retrofitting modern plate and frame heat exchangers into existing industrial infrastructure presents several challenges. Integrated heat exchangers are newer, better, more compact, and more efficient but their integration into ground-based older facilities that were designed around legacy systems is more complex inline to permit adoption without significant facility modification. Differences in piping configurations, pressure ratings, or space restrictions generally result in expensive redesigns. Furthermore, contemporary heat exchangers may utilize cutting-edge materials or intelligent monitoring technologies that cannot function with older control systems, requiring additional upgrades. Also, industries involved in continuous operations need minimum downtime to install and so it adds to the engineering complexity. Compliance with regulatory requirements can be another challenge, as new equipment may need to be certified again under new safety and efficiency standards. In addition, configurations for heat exchangers like flow rates, temperature tolerances, and thermal efficiency all have to match up to current process requirements, which can be difficult to achieve without project engineering. To overcome these limitations, strategic investment and process overhauls must be imagined and implemented, making it possible for everyone to work together harmoniously.

Plate and Frame Heat Exchanger Market Segmentation Analysis

By Type

The Gasketed segment dominated with a market share of over 52% in 2023, due to its high efficiency, flexibility, and ease of maintenance. These heat exchangers have gasket replacement capability, providing ease of cleaning and reassembly, thereby making them suitable for industries needing regular servicing like HVAC, food & beverages, chemicals, and power generation. High thermal efficiency with low energy losses makes them suitable for a wide range of commercial and industrial applications. Gasketed exchangers can also, be expanded by adding plates, providing scalability for the changing demands of processes. This also consolidates their market position as they can work with several different fluids, pressures, and temperatures. As industrialization increases and industries look for energy-efficient solutions, the gasketed heat exchangers will remain the first choice of the various industries.

By Application

The HVAC & Refrigeration segment dominated with a market share of over 32% in 2023, attributed to the common use of these components in heating, ventilation, and cooling systems across the residential, commercial, and industrial sectors. These heat exchangers improve energy efficiency through design that enhances heat transfer, and minimizes energy use and temperature control. Increasing adoption of energy-efficient HVAC solutions, backed by stringent environmental regulations and sustainability initiatives, further contributes to market growth. Its dominance is further aided by swift urbanization, rising construction activities, and the growing commercial infrastructure (shopping malls, hospitals, office buildings). The growing demand for data centers to be cooled and food to be chilled contributes to the increased market development significantly, making HVAC & Refrigeration the largest application segment in this market.

Plate and Frame Heat Exchanger Market Regional Outlook

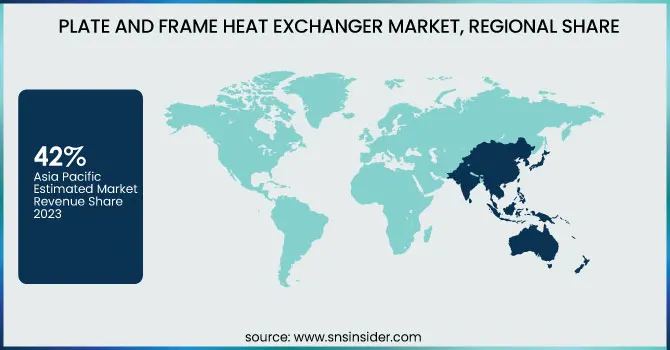

Asia-Pacific region dominated with a market share of over 42% in 2023, due to rapid industrialization and expanding infrastructure development. The increasing demand for energy in the region and the stringent regulation for energy efficiency have promoted the use and adoption of heat exchangers in different industries, such as HVAC, power generation, chemical processing, and food & beverages. With China, India, and Japan being the most prominent examples of increasing investment in industrial manufacturing and renewable energy projects, this will contribute to the growth of the market. Moreover, rising urbanization and technological advancements in heat exchange systems have increased efficiency and performance, further cementing the region’s supremacy. Increasing government initiatives toward promoting energy-efficient solutions and increasing foreign investments in the industrial sector are also expected to boost the plate and frame heat exchangers market demand.

North America is experiencing rapid growth in the Plate and Frame Heat Exchanger Market, driven by advancements in heat exchange technology and increasing demand for energy-efficient solutions. This trend is primarily fueled by it’s as a global hotspot for chemical processing, power generation, and HVAC, with its players driving innovations in cost-effective sustainable heat transfer systems to further reduce operational costs and carbon emissions. The expansion of the market is further accelerated by government regulations promoting energy efficiency and environmental suit. Furthermore, increasing renewable energy sources and industrial automation are contributing to the demand for advanced heat exchangers. North America is the fastest-growing region in this market, primarily due to the presence of key market players, ongoing R&D, and increasing infrastructure development.

Get Customized Report as per Your Business Requirement - Enquiry Now

Some of the major key players in the Plate and Frame Heat Exchanger Market

-

Alfa Laval (Gasketed Plate Heat Exchangers, Brazed Plate Heat Exchangers, Welded Plate Heat Exchangers)

-

Danfoss (Micro Plate Heat Exchangers, Brazed Plate Heat Exchangers)

-

Kelvion Holding GmbH (Gasketed Plate Heat Exchangers, Fully Welded Plate Heat Exchangers)

-

SPX Flow (Gasketed Plate Heat Exchangers, Brazed Plate Heat Exchangers)

-

XYLEM (Heat Exchanger Plates, Brazed Plate Heat Exchangers)

-

API Heat Transfer (Plate & Frame Heat Exchangers, Evaporators, Condensers)

-

H. Guntner (UK) LTD. (Compact Plate Heat Exchangers, Customized Heat Exchangers)

-

Boyd Corporation (Liquid Cold Plates, Thermal Management Solutions)

-

Johnson Controls (Gasketed Plate Heat Exchangers, Energy-Efficient Solutions)

-

Wabtec Corporation (Industrial Heat Exchangers, Plate-Fin Heat Exchangers)

-

SWEP (Brazed Plate Heat Exchangers, High-Efficiency Heat Exchangers)

-

Tranter (Gasketed Plate Heat Exchangers, Welded Plate Heat Exchangers)

-

Hisaka Works Ltd. (Gasketed Plate Heat Exchangers, Free-Flow Plate Heat Exchangers)

-

Dover Corporation (Brazed Plate Heat Exchangers, Industrial Heat Transfer Solutions)

-

Chart Industries (Plate-Fin Heat Exchangers, Welded Plate Heat Exchangers)

-

Mueller Industries (Brazed Plate Heat Exchangers, Industrial Cooling Solutions)

-

Kaori Heat Treatment Co. Ltd. (Compact Brazed Plate Heat Exchangers, High-Pressure Heat Exchangers)

-

Sondex (Gasketed Plate Heat Exchangers, Semi-Welded Plate Heat Exchangers)

-

Funke Wärmeaustauscher Apparatebau GmbH (Gasketed Plate Heat Exchangers, Fully Welded Heat Exchangers)

-

Brazetek (Brazed Plate Heat Exchangers, Residential & Commercial Heat Exchangers)

Suppliers for (high-efficiency, durable, and compact heat exchangers used in HVAC, food processing, and industrial applications) on Plate and Frame Heat Exchanger Market

-

Alfa Laval

-

Danfoss

-

Kelvion Holding GmbH

-

SPX Flow

-

AIC Heat Exchangers

-

Docal

-

MultiTherm LLC

-

Ohmstede Industrial Services

-

Taprogge GmbH

-

API Heat Transfer

RECENT DEVELOPMENT

In August 2024: SPX FLOW introduced the FastFrame series of plate heat exchangers for the food and beverage industry. Its innovative design reduces cleaning time from hours to minutes, enhancing efficiency and production. The system allows for easy disassembly and reassembly, ensuring quicker maintenance and minimal downtime.

In September 2023: Kelvion Holding GmbH expanded its production capacity in Sarstedt, allowing the facility to produce an additional 150,000 heat exchangers annually.

In March 2023: Alfa Laval introduced the T21 gasketed plate-and-frame heat exchanger (GPHE) to enhance energy efficiency across multiple industries.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 5.90 Billion |

| Market Size by 2032 | USD 10.13 Billion |

| CAGR | CAGR of 6.19% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Type (Gasketed, Welded, Brazed, Others) • By Application (HVAC & Refrigeration, Chemicals, Petrochemicals and Oil & Gas, Power Generation, Food & Beverages, Pulp & Paper, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Alfa Laval, Danfoss, Kelvion Holding GmbH, SPX Flow, XYLEM, API Heat Transfer, H. Guntner (UK) LTD., Boyd Corporation, Johnson Controls, Wabtec Corporation, SWEP, Tranter, Hisaka Works Ltd., Dover Corporation, Chart Industries, Mueller Industries, Kaori Heat Treatment Co. Ltd., Sondex, Funke Wärmeaustauscher Apparatebau GmbH, Brazetek. |