Multi-axis Motion Controller Market Size Analysis:

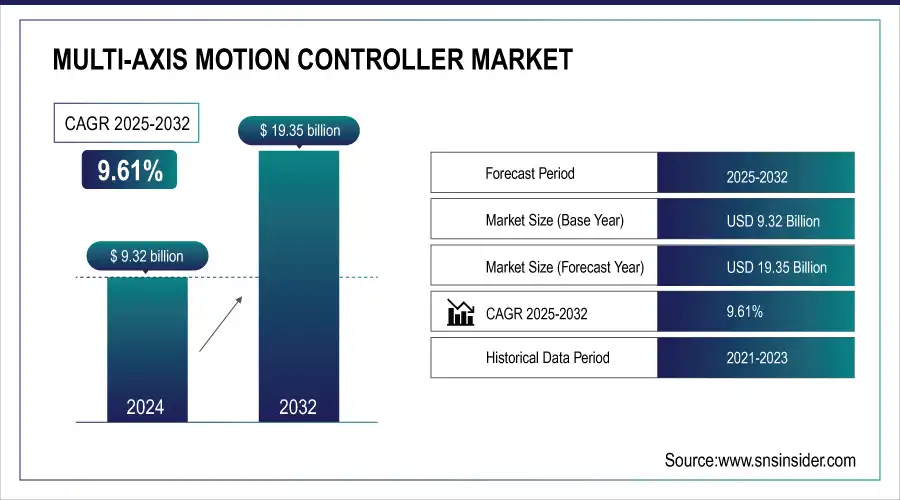

The Multi-axis Motion Controller Market size was valued at USD 9.32 billion in 2024 and is expected to reach USD 19.35 billion by 2032, growing at a CAGR of 9.61% over the forecast period of 2025-2032. The major market driver for this market is the growing requirement for industrial automation and precision control in industries, such as robotics, semiconductors, and packaging. The controllers facilitate fast, synchronized operations, and help increase productivity, efficiency, and quality on the factory floor in applications where Industry 4.0 and smart manufacturing are demanding a fully integrated IIoT manufacturing system be installed.

To Get more information On Multi-axis Motion Controller Market - Request Free Sample Report

The rising integration of advanced technologies, such as AI, IoT, and real-time monitoring in motion control systems is driving market growth. Rising requirements for high-performance and small-sized controllers in electronics assembly, 3D printing, and laser cutting are complementing the market's growth. Furthermore, the surge in demand for electric vehicles, battery production, and flexible assembly lines in smart industries is propelling market growth. Manufacturers are also looking for scalable, power-efficient solutions to meet a variety of application requirements in dynamic factory settings.

-

BMW is investing heavily in EV technology, including the development of its new "Energy Master" control module and "Neue Klasse" all-electric architecture, aiming to lead the EV market and improve efficiency, range, and energy density.

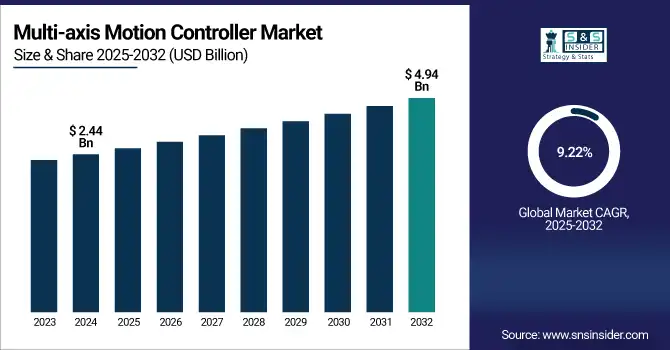

The U.S. multi-axis motion controller market size is estimated to be valued at USD 2.44 billion in 2024 and is projected to grow at a CAGR of 9.22%, reaching USD 4.94 billion by 2032. The U.S. multi-axis motion controller market is on the rise with manufacturing shift toward more automation, strong robotics uptake, and need for precise motion control in aerospace & medical devices, and investments in smart factories underpinned by AI, IoT, and sophisticated motion technologies.

Multi-axis Motion Controller Market Dynamics

Key Drivers:

-

Rising Demand for Precision Motion Control Drives Growth in Multi-axis Motion Controller with Industry 4.0

The multi-axis motion controller market growth is mainly driven by the rapid evolution of industrial automation and unprecedented demand for precision motion control in the processes of manufacturing. The rise of smart factories and the uptake of Industry 4.0 is also driving the demand for real-time and synchronized multi-axis systems, particularly in industries including electronics, automotive, packaging, and semiconductor production. For further market opportunity, there is new demand from the “green” automobile sector and electric vehicle (EV) development, in conjunction with battery production line expansion, which drives demand for high-end motion control equipment.

-

Toyota is building a 30 GWh / year battery factory in North Carolina, U.S., which will create 5,100 jobs. Those facilities utilize multi-axis motion controllers, which act as precision assembly units and quality control testing for battery production lines.

Restraints:

-

High Initial Investment and Customization Costs Challenge Adoption of Multi-axis Motion Controllers in SMEs

The high initial cost of advanced motion control systems and the high cost of customization for multi-axis motion controller act as major restraint for the market. These solutions often demand heavy investment in hardware, software, and expertise in the integration and maintenance of the systems, which becomes a barrier for small and medium-sized enterprises (SMEs) to adopt these technologies. Furthermore, when backward compatibility toward the installed base of equipment in current plants cannot be sustained, an add-on cost takes place, which raises the total cost of ownership.

Opportunities:

-

AI, IoT, and Machine Learning Transform Motion Controllers Driving Predictive Maintenance and Process Efficiency

The intersection of breakthrough technologies, including AI, machine learning, and IoT within motion controllers, is opening up new possibilities for predictive maintenance and greater process efficiencies. Multi-axis motion controller market trends show increasing demand for compact, high-speed motion systems, which are in high demand with the miniaturization of electronic and medical devices. In addition, the global trend toward energy-efficient and scalable automation solutions provide a space for vendors to develop sustainable, cost-effective controller technologies to meet the demands of dynamic production areas.

-

Implemented AI-driven predictive maintenance across its operations, leading to a 10% reduction in downtime and approximately USD 1 billion in annual savings by optimizing maintenance schedules and minimizing unexpected failures.

Challenges:

-

Securing Networked Motion Control Systems Against Cyber Threats is Crucial for Global Adoption and Scalability

The main challenge is to secure networked motion control systems. With industrial networks now incorporating the IoT, AI, and cloud platforms, they are vulnerable to cyber threats and data loss, security becomes a paramount concern. Furthermore, both on-the-fly response and accuracy are difficult to achieve in a variable network condition. Compliance with regulations and standardization of protocols between regions are additional barriers to global adoption and scalability of such systems.

Multi-axis Motion Controller Market Segmentation Analysis:

By Type

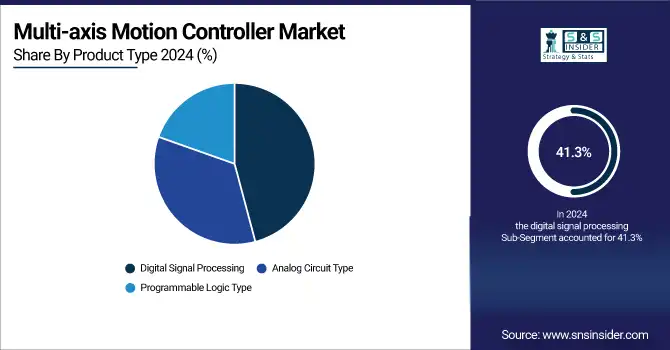

The digital signal processing (DSP) type owned a significant share of over 41.3% in the multi-axis motion controller market in 2024 as it provides greater ability to manage complex algorithms, real-time processing of data, and control accuracy for industrial automation, robotics, and CNC machinery. DSP-based controllers are also common in high-speed applications, which require fast, coordinated motion of several axes, such as, electronics pick-and-place, semiconductor manufacture, and packaging.

PL (Programmable Logic) type is anticipated to witness the highest CAGR during 2025-2032. Increasing demand for adaptable, affordable, and customizable motion control solutions in changing manufacturing landscapes is powering the growth. The programmable logic controller (PLC) will easily integrate with other industrial automation devices and is simpler to program and reprogram, making it applicable for smart factories and adaptive production lines. Their scalability and support for real-time control make them the proper solutions for the industries amid the shift toward Industry 4.0.

By Application

In 2024, the largest share of the multi-axis motion controller market was held by the robotics and CNC segment, which captured a dominating share of 29%. This fortress is due to the increasing penetration of industrial robots and CNC machines in industries that include automotive, aerospace, and heavy manufacturing, where high speed, high precision, and coordinated multi-axis movement are crucial. An increase in smart factories and the requirement for automated production lines has also led to higher demand for advanced motion controllers that can handle more complicated tasks of robots and CNCs efficiently.

The fastest-growing segment during 2025-2032 is expected to be semiconductor. This acceleration is propelled by the rapid global growth of semiconductor fabrication and packaging facilities as demand for high-performance chips in electronics, AI, and automotive sectors continues to rise. Ultra-precise positioning and timing are critical in lithography, wafer handling, and die bonding, and to that end, multi-axis motion controllers are essential.

By Offering

The multi-axis motion controller market was led by the machine tools segment, which held 31.6% of the share in 2024. The domination is heavily backed by its extensive use of machine tools for precision manufacturing across the automotive, aerospace, and metalworking sectors. These multi-axis motion controllers help enhance the accuracy, speed, and efficiency of the machine tools, which ultimately allow the production of complex components and assemblies with precise tolerances. With the automation of manufacturing processes, the demand for machine tools with advanced motion control systems is growing.

The fastest CAGR is projected to be witnessed by the semiconductor segment during 2025-2032. As demand for products that require microchips including consumer electronics, electric vehicles, and Internet of Things devices, continues to soar, the semiconductor industry is witnessing rapid expansion, which is driving this growth. High-precision and synchronized motion are necessary for semiconductor manufacturing processes such as wafer handling, photolithography, and inspection, which makes a vital role for a multi-axis motion controller.

Multi-axis Motion Controller Market Regional Analysis:

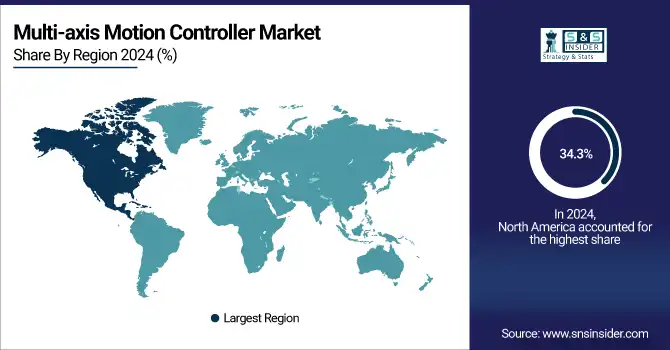

North America dominated the multi-axis motion controller market share with 34.3% in 2024. The strong manufacturing base of the region, the implementation of high automation technologies, and a quick transition to Industry 4.0 standards are some of the factors leading to a high market share in the region. The U.S. has always been at the forefront of adapting robotics, AI, and IoT into industrial systems. High-precision motion controllers are widely used in industries, such as automotive, aerospace, electronics, and semiconductor manufacturing; hence, the rise in demand from these industries is also driving the market growth.

Get Customized Report as per Your Business Requirement - Enquiry Now

The North American multi-axis motion controller market is dominated by the U.S. The growth is driven by the established manufacturing ecosystem, proliferation of automation & robotics companies, and the adoption of Industry 4.0 related technologies across the automotive, aerospace & defense, and semiconductor industries in the region,

The Asia Pacific region is anticipated to grow at the fastest CAGR of 21.4% from 2025- 2032. It is due to the fast industrialization in countries like China, Japan, South Korea, and India. Growth in this region is being stimulated by rising demand for robotics, smart manufacturing, and advanced automation across the region's booming automotive, electronics, and semiconductor sectors. Asia Pacific is a significant demand region for high-performance motion controllers owing to the large-scale manufacturing capabilities, massive investments in technology, lighting, and concrete infrastructure.

China leads the Asia Pacific multi-axis motion controller market, owing to a larger manufacturing base coupled with fast-paced industrial automation, government-supported smart factory initiatives, and burgeoning electronics, automotive, and semiconductor industries with a high requirement for precision motion control systems.

Europe is concentrating on precision engineering, smart manufacturing, and energy-efficient automation, which is driving the multi-axis motion controller market in this region. The growing penetration of advanced motion control solutions across automotive, aerospace, packaging, and medical device industries to ensure maximum productivity and compliance with stringent safety and efficiency standards will drive the demand for motion control devices in these key industrial sectors.

With world-class engineering and automation capabilities as well as the critical mass of these industries, Germany dominates European multi-axis motion controller revenue, especially in the automotive and machinery sectors. The early adoption of Industry 4.0 further drives demand for it.

Latin America and the Middle East & Africa (MEA) are developing regions in the multi-axis motion controller market, which are also adopting the technology gradually, owing to increasing industrial automation and developments in infrastructure. The growth of the market can be attributed to the growing investments in packaging, automotive, and material handling sectors, paired with rising awareness about the advantages offered by smart manufacturing.

Multi-axis Motion Controller Companies are:

Some of the major multi-axis motion controller companies are Siemens, ABB, Mitsubishi Electric, Schneider Electric, Yaskawa, Delta Electronics, Omron, Panasonic Industry, Rockwell Automation, and Aerotech.

Recent News:

-

In April 2024, Siemens unveiled the Simatic S7-1200 G2, a next-gen controller offering enhanced performance, scalability, and integrated safety features. Part of Siemens Xcelerator, it streamlines automation tasks and will be available commercially.

-

In January 2024, Yaskawa Electric Corporation launched the MPX1000 series controllers, featuring the MPX1310, designed for high-speed, synchronized multi-axis control with up to 128 axes.

| Report Attributes | Details |

|---|---|

| Market Size in 2024 | USD 9.32 Billion |

| Market Size by 2032 | USD 19.35 Billion |

| CAGR | CAGR of 9.61% From 2025 to 2032 |

| Base Year | 2024 |

| Forecast Period | 2025-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Product Type (Digital Signal Processing Type, Analog Circuit Type, Programmable Logic Type) • By Application (GMC, Material Handling, Robotics and CNC, Packaging and Labeling, Semiconductor Process, Flight Simulator, Semiconductor) • By End User (Packaging and Labeling, Machine Tools, Material Handling, Semiconductor, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Siemens, ABB, Mitsubishi Electric, Schneider Electric, Yaskawa, Delta Electronics, Omron, Panasonic Industry, Rockwell Automation, and Aerotech. |