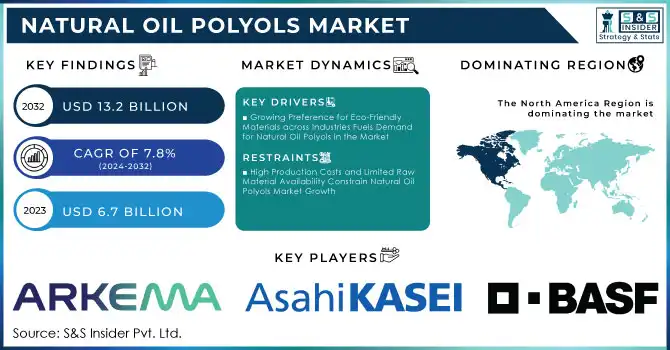

Natural Oil Polyols Market Key Insights:

The Natural Oil Polyols Market Size was valued at USD 6.7 billion in 2023 and is expected to reach USD 13.2 billion by 2032 and grow at a CAGR of 7.8% over the forecast period 2024-2032. The Natural Oil Polyols Market is witnessing significant growth due to increased demand for sustainable materials in various industries, including automotive, construction, and furniture. With natural oil polyols derived from vegetable oils, the market provides an eco-friendly alternative to petroleum-based polyols, reducing reliance on fossil fuels and lowering carbon emissions. Leading companies are investing in innovative technologies to improve both the production and performance of these polyols. In May 2024, Chimcomplex expanded its green polyol production capacity in Romania to meet the rising demand for sustainable alternatives. This expansion aligns with Chimcomplex’s commitment to providing environmentally friendly products in response to stricter regulations and growing consumer preferences.

To Get More Information on Natural Oil Polyols Market - Request Sample Report

Additionally, in July 2022, Manali Petrochemicals partnered with the United Kingdom's Econic Technologies to introduce advanced carbon capture technology into its polyol manufacturing process. This collaboration enables the incorporation of carbon dioxide in polyol production, which reduces overall emissions and enhances sustainability. Such partnerships and investments are essential in addressing the growing demand for greener products, making natural oil polyols increasingly attractive across sectors.

Innovation and research further underscore the market’s dynamic growth, as companies pursue diverse feedstock options and eco-friendly production techniques. In October 2019, Indian researchers developed polyols from rubber seed oil, expanding the sources of raw materials available for polyol production. This innovation showcases the industry's commitment to sustainable practices by diversifying the bio-based inputs in polyol manufacturing. Chimcomplex’s efforts continued with a green investment at its Ramnicu Valcea plant in May 2024, focusing on ecological polyols. This initiative further strengthens Chimcomplex’s presence in the European market, reflecting its dedication to meeting the demand for green materials. As key players like Chimcomplex and Manali Petrochemicals drive forward with sustainable technologies and diversified feedstocks, the Natural Oil Polyols Market is well-positioned to meet regulatory and consumer demands for environmentally responsible products.

Market Dynamics

Drivers

-

Growing Preference for Eco-Friendly Materials across Industries Fuels Demand for Natural Oil Polyols in the Market

As environmental regulations tighten globally, industries such as automotive, construction, and consumer goods are shifting towards eco-friendly materials, boosting the demand for natural oil polyols. Derived from renewable sources like soy, castor, and rapeseed oil, these polyols are biodegradable and contribute to reducing carbon emissions, making them an attractive alternative to petroleum-based polyols. With consumers prioritizing sustainable products, brands are adopting bio-based polyols for manufacturing products that align with these values. For instance, in the automotive sector, natural oil polyols are used to produce lightweight polyurethane foams for car interiors, enhancing fuel efficiency. Similarly, construction materials made from natural oil polyols offer both durability and environmental benefits, helping companies comply with sustainability goals. This strong industry-wide push toward green chemistry is a critical driver for the Natural Oil Polyols Market, positioning it as a pivotal component in the shift toward sustainable manufacturing.

-

Rising Investments in Research and Development Drive Innovation in Natural Oil Polyol-Based Products and Applications

The growing interest in sustainable alternatives has led to increased investments in research and development for enhancing the performance and application range of natural oil polyols. Key industry players and research institutions are collaborating to improve the bio-based content, durability, and overall efficiency of natural oil polyols to meet the specific requirements of end-use sectors. Innovations such as using rubber seed oil or carbon capture technology in polyol production exemplify how companies are striving to diversify raw materials and make manufacturing processes more sustainable. These R&D efforts not only help companies expand their natural oil polyol portfolios but also foster product differentiation in a competitive market. Additionally, R&D initiatives are focused on improving the cost-effectiveness of natural oil polyols, making them more accessible across industries and applications. With continued investment, the potential for bio-based polyols to replace petroleum-derived alternatives is increasingly promising, creating growth momentum in the Natural Oil Polyols Market.

Restraint

-

High Production Costs and Limited Raw Material Availability Constrain Natural Oil Polyols Market Growth

One of the major restraints facing the Natural Oil Polyols Market is the high production cost associated with bio-based polyols, largely due to the expenses involved in processing natural oils and the limited availability of raw materials. Unlike petroleum-based polyols, natural oil polyols are dependent on agricultural feedstocks, which are subject to seasonal fluctuations, price variability, and supply chain disruptions. Furthermore, the extraction and refinement processes for natural oil polyols require advanced technologies and significant energy, which contribute to higher operational costs. These factors can limit the affordability and widespread adoption of natural oil polyols, particularly for cost-sensitive industries. Additionally, reliance on specific crops, such as soy or castor, for raw materials can lead to competition with other agricultural applications, further impacting the supply chain. Consequently, the high production costs and limited raw material availability pose challenges to scaling up the production of natural oil polyols on a global level.

Opportunity

-

Expanding Applications in Emerging Markets Present Growth Opportunities for Natural Oil Polyols Market

Emerging markets, particularly in Asia-Pacific and Latin America, are presenting new growth opportunities for the Natural Oil Polyols Market, driven by increasing awareness of sustainable products and expanding industrial activities. As these regions experience industrialization and urbanization, the demand for eco-friendly products in sectors like construction, automotive, and furniture is rising. Natural oil polyols, with their renewable origin and low environmental impact, are finding traction as sustainable substitutes for petroleum-based polyols. Local manufacturers in these markets are also investing in sustainable practices to align with global standards, further fueling demand. Additionally, supportive government initiatives in countries such as China and India are promoting the adoption of bio-based materials, enhancing the market’s growth prospects. These expanding applications in emerging economies represent a significant opportunity for companies to capture new markets and diversify their customer base while advancing sustainability objectives.

Challenge

-

Complex Production Processes and Technological Challenges Impacting Large-Scale Adoption of Natural Oil Polyols

The production of natural oil polyols involves complex processes that require specialized technology and knowledge, which can present challenges to large-scale adoption. Converting natural oils into polyols necessitates chemical modifications that ensure the product meets specific performance standards, such as durability, flexibility, and thermal stability. These processes often require high energy input and advanced catalysts, making the overall production more challenging and costly than conventional polyol manufacturing. Additionally, the technical complexity involved in refining the product to match the quality of petroleum-based polyols means that manufacturers need substantial R&D investments, which can limit market entry for smaller companies. Furthermore, maintaining consistent quality and performance while minimizing environmental impact adds to the technological hurdles. These challenges underscore the need for continued innovation and process optimization to make natural oil polyol production viable on a larger scale, ultimately affecting its widespread adoption.

Key Segmentation Analysis

By Product Type

The Soy Oil segment dominated the Natural Oil Polyols Market in 2023, holding a market share of around 35%. This dominance is largely due to soy oil’s widespread availability and favorable cost, making it a popular choice for bio-based polyol production. As a renewable feedstock, soy oil is valued for its versatility and eco-friendly profile, contributing to its extensive use in polyurethane (PU) foam applications. For example, the furniture and bedding industries often utilize soy-based polyols to produce flexible and durable foams for mattresses and cushions, meeting consumer demand for sustainable products. Additionally, soy oil polyols offer a good balance of cost and performance, making them suitable for diverse applications ranging from automotive interiors to construction materials, further solidifying their market-leading position.

By Application

The Polyurethane Foams (PU) segment dominated the Natural Oil Polyols Market in 2023, accounting for approximately 40% of the market share. PU foam applications benefit significantly from natural oil polyols due to their flexibility, durability, and environmental benefits. Natural oil-based PU foams are extensively used in automotive interiors, furniture, and bedding, offering both comfort and a reduced carbon footprint. For instance, automotive manufacturers are increasingly opting for bio-based PU foams in seating and interior components to align with sustainability goals. Similarly, in the furniture sector, companies are leveraging PU foam derived from natural oil polyols to create eco-friendly products that meet consumer demand for sustainable alternatives. This broad applicability across various end-user sectors has propelled the PU Foam segment to lead the market.

By End-use Industry

The Automotive segment dominated the Natural Oil Polyols Market in 2023, with a market share of around 30%. Automotive manufacturers are increasingly adopting natural oil polyols, especially polyurethane foams for seating, insulation, and soundproofing components, to reduce their environmental footprint. Bio-based polyols offer a lightweight and sustainable alternative to traditional materials, helping improve vehicle fuel efficiency and meet regulatory standards. Leading automakers are also focusing on integrating green materials as part of their sustainability strategies, contributing to the strong demand for natural oil polyols in this sector. Additionally, automotive applications of these polyols are supported by innovations in bio-based PU foams that provide the durability and comfort required for vehicle interiors, reinforcing the automotive sector’s leadership in the market.

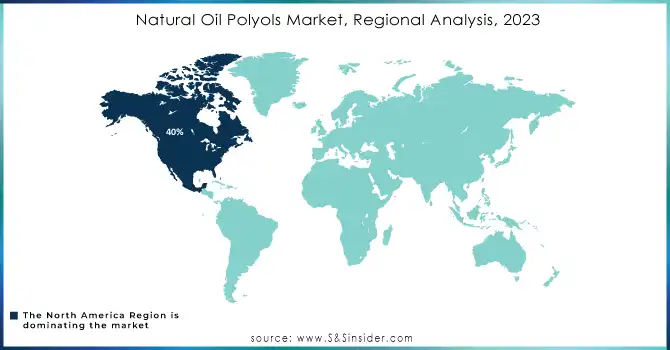

Regional Analysis

North America dominated the Natural Oil Polyols Market in 2023, holding an estimated market share of around 40%. This region's leadership is attributed to its advanced manufacturing capabilities, robust demand for sustainable and eco-friendly products, and strong governmental regulations promoting green chemistry. The United States, in particular, plays a significant role in this dominance, with a large number of polyurethane manufacturers shifting to bio-based polyols in response to both consumer demand and stricter environmental standards. For example, companies like BASF and Dow Inc. have been at the forefront of incorporating sustainable practices into their production lines, focusing on bio-based polyols derived from soy, castor, and palm oils. Furthermore, the U.S. automotive industry is heavily integrating natural oil-based polyols in foam production for car interiors and seats, reflecting the growing demand for sustainable solutions. The construction sector in North America is also adopting bio-based polyols in insulation materials, coatings, and adhesives to align with sustainability goals. Canada, with its significant production of canola oil, has emerged as a key supplier of natural oil polyols in the region, bolstering the North American market’s dominance. The region's favorable economic environment and ongoing investments in green technologies ensure its continued leadership in the Natural Oil Polyols Market.

Moreover, Asia-Pacific emerged as the fastest growing region in the Natural Oil Polyols Market in 2023, with a CAGR of 7%. The rapid industrialization and increasing awareness about environmental sustainability are the primary drivers of this growth. China and India, in particular, are spearheading this expansion due to their growing automotive, construction, and packaging sectors, where there is a rising demand for eco-friendly alternatives to traditional petrochemical products. In China, the government's push for green initiatives, alongside the increasing consumer preference for sustainable products, is accelerating the adoption of natural oil polyols in manufacturing processes. For example, major automotive companies in China are integrating bio-based polyurethane foams in car seats and interiors, which are derived from renewable natural oil sources like soy and castor oil. Similarly, India’s rapidly growing construction industry is adopting natural oil polyols in coatings, adhesives, and insulation materials, driven by both demand for eco-friendly solutions and government incentives for sustainable building practices. The expansion of the bio-based polyol production infrastructure in countries like China and India is expected to support the region’s robust growth, with a rising number of local producers entering the market to cater to the increasing demand for natural oil polyols in diverse applications. With its expanding manufacturing base, strong government policies, and a focus on sustainability, the Asia-Pacific region is expected to continue growing at a rapid pace, making it the fastest-growing market for natural oil polyols.

Do You Need any Customization Research on Natural Oil Polyols Market - Inquire Now

Recent Developments

-

May 2024: Chimcomplex SA Borzesti completed a €40 million expansion of its green polyol production capacity in Romania, increasing output by 17,000 tons annually. The plant now uses eco-friendly raw materials, such as castor and soybean oils, and aims to reduce CO2 emissions by 3,400 tons. The project was co-financed by Innovation Norway and strengthens the company’s commitment to sustainability.

-

March 2023: Perstorp Holding AB launched two new polyol grades, Evyron T100 and Neeture N100, both made from 100% renewable sources. These products, designed to reduce carbon footprints, support renewable and recycled raw materials, enhancing the company's position as a leader in low-carbon chemicals.

Key Players

-

Arkema S.A. (Rilsan PA11, Rilsamid PA12)

-

Asahi Kasei Corporation (Leona PA66, Tenac PA12)

-

BASF SE (Ultramid PA6, Ultramid Ccycled PA66)

-

Cathay Biotech Inc. (Terryl PA56, Terryl PA510)

-

Domo Chemicals (Technyl PA6, Technyl Star PA66)

-

DuPont de Nemours, Inc. (Zytel PA66, Hytrel PA12)

-

EMS-Chemie Holding AG (Grilamid PA12, Grilon PA6)

-

Evonik Industries AG (Vestamid PA12, Vestamid Terra PA610)

-

Grupa Azoty S.A. (Tarnamid PA6, Tarnamid PA66)

-

Honeywell International Inc. (Aegis PA6, Capron PA66)

-

Invista (Torzen PA66, Cordura PA6)

-

LANXESS AG (Durethan PA6, Durethan ECO PA66)

-

Li Peng Enterprise Co., Ltd. (Zig Sheng PA6, Zig Sheng PA66)

-

Mitsubishi Chemical Corporation (Durabio PA6, Diamiron PA66)

-

Radici Group (Radilon PA6, Radilon A PA66)

-

Royal DSM N.V. (EcoPaXX PA410, Arnitel PA12)

-

Sabic (Ultramid PA6, Ultem PA12)

-

Solvay S.A. (Bio Amni PA610, Technyl eXten PA610)

-

Toray Industries, Inc. (Amilan PA66, Toraycon PA6)

-

Ube Industries, Ltd. (UBESTA PA12, UBESTA XPA PA6)

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | US$ 6.7 Billion |

| Market Size by 2032 | US$ 13.2 Billion |

| CAGR | CAGR of 7.8% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | •By Product Type (Soy Oil, Castor Oil, Palm Oil, Canola Oil, Sunflower Oil, Others) •By Application (Polyurethane (PU) Foam, Coatings & Adhesives, Sealants, Elastomers, Lubricants, Others) •By End-User Industry (Automotive, Construction, Furniture & Bedding, Packaging, Electronics, Personal Care, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | BASF SE, The Dow Chemical Company, Emery Oleochemicals, Cargill, Incorporated, Arkema S.A., Bayer MaterialScience AG, Vertellus Holdings LLC, Stepan Company, Croda International Plc, Ipanex and other key players |

| Key Drivers | •Growing Preference for Eco-Friendly Materials across Industries Fuels Demand for Natural Oil Polyols in the Market • Rising Investments in Research and Development Drive Innovation in Natural Oil Polyol-Based Products and Applications |

| Restraints | • High Production Costs and Limited Raw Material Availability Constrain Natural Oil Polyols Market Growth |