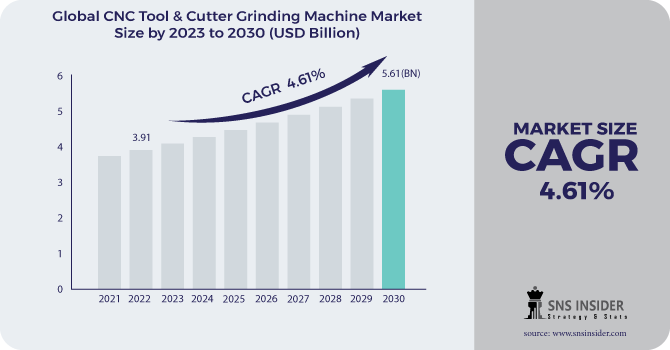

CNC Tool & Cutter Grinding Machine Market size was valued at USD 4.26 Bn in 2023 and is expected to reach USD 6.13 Bn by 2031 With a growing CAGR of 4.63 % over the forecast period 2024-2031.

Tool and cutter grinding machines with computer numerical control (CNC) are used to sharpen milling cutters, tool bits, and other cutting tools. These machines are flexible, and they may be used to grind a range of surfaces, cylindrical forms, and complicated shapes. By automating the whole process, these devices increase production rates. The automated tool loading capability and the ability to use several grinding wheels increase productivity. To make diverse components, these instruments employ computer-aided design (CAD) and computer-aided manufacturing (CAM) software.

To get more information on CNC Tool & Cutter Grinding Machine Market - Request Free Sample Report

MARKET DYNAMICS

KEY DRIVERS

Manufacturing Sector Development.

The Automotive Industry is Growing.

RESTRAINTS

High Capital investment.

Required Skilled labor.

OPPORTUNITY

The Internet of Things (IoT) and machine learning's ongoing growth.

Following that, CNC machines were used to mass-produce components.

IMPACT OF COVID-19:

The pandemic has been labeled a healthcare emergency, and as a result, the world's strong healthcare service providers and infrastructures are failing, causing an increase in the level of suffering. Rising pandemic cases are being taken into account, and worldwide governments are working on preventing the virus from spreading. As a result, worldwide governments were obliged to establish legislation and implement harsh restrictions that would have an impact on the functioning but might assist slow the spread of the epidemic internationally. However, the tight restrictions adopted, such as the lockdown, had a significant influence on market functioning, resulting in a substantial disruption in the worldwide market's supply chain mechanism. Furthermore, the market has been plagued by manufacturing and production challenges, which have acted as a fundamental fault and resulted in lower demand. During the projected period, which ends in 2030, demand is also declining due to shifting market trends and tastes of the worldwide audience. As a result, worldwide CNC Tool & Cutter Grinding Machine Market companies are recognizing shifting trends and investing in research and development. This is a critical step that will assist the market in developing new and creative products and launching them on a global basis.

MARKET ESTIMATION:

The market has been divided into three types of grinding machines: blank and cylindrical grinding machines, universal grinding machines, and tool and cutter grinding machines. Due to increasing demand from the engineering, aerospace, and automotive industries, the blank and cylindrical grinding machine segment is likely to dominate the market throughout the forecast period. Cylindrical grinding machines are used to shape the outside surfaces of components like tubes and rods.

Automotive, aerospace and defense, and electrical and electronics production are all major market applications. During the forecast period, the automotive segment is expected to dominate the market. CNC tool cutters and grinding machines have been used to make prototypes for new machines and large-scale component production. Consumer demand for automobiles is expected to grow in Japan, China, and India in the future years. Metal fabrication digitization, along with shorter manufacturing times, is predicted to boost segment growth.

By Type

Tool & Cutter Grinding Machine

Universal Grinding Machine

Blank and Cylindrical Grinding Machines

By Application

Electrical and Electronics Manufacturing

Aerospace & Defense

Automotive

.png)

Need any customization research on CNC Tool & Cutter Grinding Machine Market - Enquiry Now

REGIONAL ANALYSIS:

By 2030, the Asia Pacific market is predicted to have the largest share of the industry. During the predicted period, it is expected to expand at a positive rate. Market demand is expected to be boosted by the presence of subsidiaries of major consumer electronics, automobile, and machine tool manufacturers. The rate of growth is aided by consistent growth and demand throughout China, South Korea, Japan, and India's economies.

Because of the existence of numerous heavy industries in the region, the North American market has significant development potential. The market growth might be aided by investments in the aerospace, defense, and automotive industries, as well as robust distribution channels.

North America

US

Canada

Mexico

Europe

Eastern Europe

Poland

Romania

Hungary

Turkey

Rest of Eastern Europe

Western Europe

Germany

France

UK

Italy

Spain

Netherlands

Switzerland

Austria

Rest of Western Europe

Asia Pacific

China

India

Japan

South Korea

Vietnam

Singapore

Australia

Rest of Asia Pacific

Middle East & Africa

Middle East

UAE

Egypt

Saudi Arabia

Qatar

Rest of the Middle East

Africa

Nigeria

South Africa

Rest of Africa

Latin America

Brazil

Argentina

Colombia

Rest of Latin America

The major players are Vollmer, Makino Milling Machine Co., Ltd., Haas Automation, Inc., ANCA Pty Ltd., ISOG Technology GmbH, JTEKT Corp, Korber AG, Amada Machine Tools Co., Ltd., DANOBAT Group, WIDMA Machine Tools, Rollomatic SA, and others In Final Report

Makino Milling Machine Co Ltd-Company Financial Analysis

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | US$ 4.26 Billion |

| Market Size by 2031 | US$ 6.13 Billion |

| CAGR | CAGR 4.63% From 2024 to 2031 |

| Base Year | 2022 |

| Forecast Period | 2024-2031 |

| Historical Data | 2020-2021 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • by Type (Tool & Cutter Grinding Machine, Universal Grinding Machine, Blank and Cylindrical Grinding Machines) • by Application (Electrical and Electronics Manufacturing, Aerospace & Defense, Automotive) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Vollmer, Makino Milling Machine Co., Ltd., Haas Automation, Inc., ANCA Pty Ltd., ISOG Technology GmbH, JTEKT Corp, Korber AG, Amada Machine Tools Co., Ltd., DANOBAT Group, WIDMA Machine Tools, Rollomatic SA. |

| Key Drivers | •Manufacturing Sector Development. •The Automotive Industry is Growing. |

| Restraints | •High Capital investment. •Required Skilled labor. |

Ans: - The CNC Tool & Cutter Grinding Machine Market size was valued at USD 4.26 Bn in 2023.

Ans: Manufacturing Sector Development and the Automotive Industry is Growing.

Ans: - The Asia Pacific region controls the majority of the CNC Tool & Cutter Grinding Machine market.

Ans: - The major key players are Vollmer, Makino Milling Machine Co., Ltd., J Schneeberger Maschinen AG, Haas Automation, Inc., ANCA Pty Ltd., DANOBAT ISOG Technology GmbH, JTEKT Corp, Korber AG, Amada Machine Tools Co., Ltd., Gebr. SAACKE GmbH & Co. KG, WIDMA Machine Tools, Rollomatic SA, Alfred H. Schütte GmbH & Co. KG, Gleason Corporation, and JUNKER Group.

Ans: - The CNC Tool & Cutter Grinding Machine Market is growing at a CAGR of 4.63% From 2024 to 2031.

Table of Contents

1. Introduction

1.1 Market Definition

1.2 Scope

1.3 Research Assumptions

2. Industry Flowchart

3. Research Methodology

4. Market Dynamics

4.1 Drivers

4.2 Restraints

4.3 Opportunities

4.4 Challenges

5. Impact Analysis

5.1 Impact Of Russia Ukraine Crisis

5.2 Impact of Economic Slowdown on Major Countries

5.2.1 Introduction

5.2.2 United States

5.2.3 Canada

5.2.4 Germany

5.2.5 France

5.2.6 UK

5.2.7 China

5.2.8 Japan

5.2.9 South Korea

5.2.10 India

6. Value Chain Analysis

7. Porter’s 5 Forces Model

8. Pest Analysis

9. CNC Tool & Cutter Grinding Machine Market Segmentation, By Type

9.1 Introduction

9.2 Trend Analysis

9.3 Tool & Cutter Grinding Machine

9.4 Universal Grinding Machine

9.5 Blank and Cylindrical Grinding Machines

10. CNC Tool & Cutter Grinding Machine Market Segmentation, By Application

10.2 Trend Analysis

10.3 Electrical and Electronics Manufacturing

10.4 Aerospace & Defense

10.5 Automotive

11. Regional Analysis

11.1 Introduction

11.2 North America

11.2.1 Trend Analysis

11.2.2 North America CNC Tool & Cutter Grinding Machine Market by Country

11.2.3 North America CNC Tool & Cutter Grinding Machine Market By Type

11.2.4 North America CNC Tool & Cutter Grinding Machine Market By Application

11.2.5 USA

11.2.5.1 USA CNC Tool & Cutter Grinding Machine Market By Type

11.2.5.2 USA CNC Tool & Cutter Grinding Machine Market By Application

11.2.6 Canada

11.2.6.1 Canada CNC Tool & Cutter Grinding Machine Market By Type

11.2.6.2 Canada CNC Tool & Cutter Grinding Machine Market By Application

11.2.7 Mexico

11.2.7.1 Mexico CNC Tool & Cutter Grinding Machine Market By Type

11.2.7.2 Mexico CNC Tool & Cutter Grinding Machine Market By Application

11.3 Europe

11.3.1 Trend Analysis

11.3.2 Eastern Europe

11.3.2.1 Eastern Europe CNC Tool & Cutter Grinding Machine Market by Country

11.3.2.2 Eastern Europe CNC Tool & Cutter Grinding Machine Market By Type

11.3.2.3 Eastern Europe CNC Tool & Cutter Grinding Machine Market By Application

11.3.2.4 Poland

11.3.2.4.1 Poland CNC Tool & Cutter Grinding Machine Market By Type

11.3.2.4.2 Poland CNC Tool & Cutter Grinding Machine Market By Application

11.3.2.5 Romania

11.3.2.5.1 Romania CNC Tool & Cutter Grinding Machine Market By Type

11.3.2.5.2 Romania CNC Tool & Cutter Grinding Machine Market By Application

11.3.2.6 Hungary

11.3.2.6.1 Hungary CNC Tool & Cutter Grinding Machine Market By Type

11.3.2.6.2 Hungary CNC Tool & Cutter Grinding Machine Market By Application

11.3.2.7 Turkey

11.3.2.7.1 Turkey CNC Tool & Cutter Grinding Machine Market By Type

11.3.2.7.2 Turkey CNC Tool & Cutter Grinding Machine Market By Application

11.3.2.8 Rest of Eastern Europe

11.3.2.8.1 Rest of Eastern Europe CNC Tool & Cutter Grinding Machine Market By Type

11.3.2.8.2 Rest of Eastern Europe CNC Tool & Cutter Grinding Machine Market By Application

11.3.3 Western Europe

11.3.3.1 Western Europe CNC Tool & Cutter Grinding Machine Market by Country

11.3.3.2 Western Europe CNC Tool & Cutter Grinding Machine Market By Type

11.3.3.3 Western Europe CNC Tool & Cutter Grinding Machine Market By Application

11.3.3.4 Germany

11.3.3.4.1 Germany CNC Tool & Cutter Grinding Machine Market By Type

11.3.3.4.2 Germany CNC Tool & Cutter Grinding Machine Market By Application

11.3.3.5 France

11.3.3.5.1 France CNC Tool & Cutter Grinding Machine Market By Type

11.3.3.5.2 France CNC Tool & Cutter Grinding Machine Market By Application

11.3.3.6 UK

11.3.3.6.1 UK CNC Tool & Cutter Grinding Machine Market By Type

11.3.3.6.2 UK CNC Tool & Cutter Grinding Machine Market By Application

11.3.3.7 Italy

11.3.3.7.1 Italy CNC Tool & Cutter Grinding Machine Market By Type

11.3.3.7.2 Italy CNC Tool & Cutter Grinding Machine Market By Application

11.3.3.8 Spain

11.3.3.8.1 Spain CNC Tool & Cutter Grinding Machine Market By Type

11.3.3.8.2 Spain CNC Tool & Cutter Grinding Machine Market By Application

11.3.3.9 Netherlands

11.3.3.9.1 Netherlands CNC Tool & Cutter Grinding Machine Market By Type

11.3.3.9.2 Netherlands CNC Tool & Cutter Grinding Machine Market By Application

11.3.3.10 Switzerland

11.3.3.10.1 Switzerland CNC Tool & Cutter Grinding Machine Market By Type

11.3.3.10.2 Switzerland CNC Tool & Cutter Grinding Machine Market By Application

11.3.3.11 Austria

11.3.3.11.1 Austria CNC Tool & Cutter Grinding Machine Market By Type

11.3.3.11.2 Austria CNC Tool & Cutter Grinding Machine Market By Application

11.3.3.12 Rest of Western Europe

11.3.3.12.1 Rest of Western Europe CNC Tool & Cutter Grinding Machine Market By Type

11.3.2.12.2 Rest of Western Europe CNC Tool & Cutter Grinding Machine Market By Application

11.4 Asia-Pacific

11.4.1 Trend Analysis

11.4.2 Asia Pacific CNC Tool & Cutter Grinding Machine Market by Country

11.4.3 Asia Pacific CNC Tool & Cutter Grinding Machine Market By Type

11.4.4 Asia Pacific CNC Tool & Cutter Grinding Machine Market By Application

11.4.5 China

11.4.5.1 China CNC Tool & Cutter Grinding Machine Market By Type

11.4.5.2 China CNC Tool & Cutter Grinding Machine Market By Application

11.4.6 India

11.4.6.1 India CNC Tool & Cutter Grinding Machine Market By Type

11.4.6.2 India CNC Tool & Cutter Grinding Machine Market By Application

11.4.7 Japan

11.4.7.1 Japan CNC Tool & Cutter Grinding Machine Market By Type

11.4.7.2 Japan CNC Tool & Cutter Grinding Machine Market By Application

11.4.8 South Korea

11.4.8.1 South Korea CNC Tool & Cutter Grinding Machine Market By Type

11.4.8.2 South Korea CNC Tool & Cutter Grinding Machine Market By Application

11.4.9 Vietnam

11.4.9.1 Vietnam CNC Tool & Cutter Grinding Machine Market By Type

11.4.9.2 Vietnam CNC Tool & Cutter Grinding Machine Market By Application

11.4.10 Singapore

11.4.10.1 Singapore CNC Tool & Cutter Grinding Machine Market By Type

11.4.10.2 Singapore CNC Tool & Cutter Grinding Machine Market By Application

11.4.11 Australia

11.4.11.1 Australia CNC Tool & Cutter Grinding Machine Market By Type

11.4.11.2 Australia CNC Tool & Cutter Grinding Machine Market By Application

11.4.12 Rest of Asia-Pacific

11.4.12.1 Rest of Asia-Pacific CNC Tool & Cutter Grinding Machine Market By Type

11.4.12.2 Rest of Asia-Pacific CNC Tool & Cutter Grinding Machine Market By Application

11.5 Middle East & Africa

11.5.1 Trend Analysis

11.5.2 Middle East

11.5.2.1 Middle East CNC Tool & Cutter Grinding Machine Market by Country

11.5.2.2 Middle East CNC Tool & Cutter Grinding Machine Market By Type

11.5.2.3 Middle East CNC Tool & Cutter Grinding Machine Market By Application

11.5.2.4 UAE

11.5.2.4.1 UAE CNC Tool & Cutter Grinding Machine Market By Type

11.5.2.4.2 UAE CNC Tool & Cutter Grinding Machine Market By Application

11.5.2.5 Egypt

11.5.2.5.1 Egypt CNC Tool & Cutter Grinding Machine Market By Type

11.5.2.5.2 Egypt CNC Tool & Cutter Grinding Machine Market By Application

11.5.2.6 Saudi Arabia

11.5.2.6.1 Saudi Arabia CNC Tool & Cutter Grinding Machine Market By Type

11.5.2.6.2 Saudi Arabia CNC Tool & Cutter Grinding Machine Market By Application

11.5.2.7 Qatar

11.5.2.7.1 Qatar CNC Tool & Cutter Grinding Machine Market By Type

11.5.2.7.2 Qatar CNC Tool & Cutter Grinding Machine Market By Application

11.5.2.8 Rest of Middle East

11.5.2.8.1 Rest of Middle East CNC Tool & Cutter Grinding Machine Market By Type

11.5.2.8.2 Rest of Middle East CNC Tool & Cutter Grinding Machine Market By Application

11.5.3 Africa

11.5.3.1 Africa CNC Tool & Cutter Grinding Machine Market by Country

11.5.3.2 Africa CNC Tool & Cutter Grinding Machine Market By Type

11.5.3.3 Africa CNC Tool & Cutter Grinding Machine Market By Application

11.5.2.4 Nigeria

11.5.2.4.1 South Africa CNC Tool & Cutter Grinding Machine Market By Type

11.5.2.4.2 South Africa CNC Tool & Cutter Grinding Machine Market By Application

11.5.2.5 South Africa

11.5.2.5.1 South Africa CNC Tool & Cutter Grinding Machine Market By Type

11.5.2.5.2 South Africa CNC Tool & Cutter Grinding Machine Market By Application

11.5.2.6 Rest of Africa

11.5.2.6.1 Rest of Africa CNC Tool & Cutter Grinding Machine Market By Type

11.5.2.6.2 Rest of Africa CNC Tool & Cutter Grinding Machine Market By Application

11.6 Latin America

11.6.1 Trend Analysis

11.6.2 Latin America CNC Tool & Cutter Grinding Machine Market by Country

11.6.3 Latin America CNC Tool & Cutter Grinding Machine Market By Type

11.6.4 Latin America CNC Tool & Cutter Grinding Machine Market By Application

11.6.5 Brazil

11.6.5.1 Brazil CNC Tool & Cutter Grinding Machine Market By Type

11.6.5.2 Brazil CNC Tool & Cutter Grinding Machine Market By Application

11.6.6 Argentina

11.6.6.1 Argentina CNC Tool & Cutter Grinding Machine Market By Type

11.6.6.2 Argentina CNC Tool & Cutter Grinding Machine Market By Application

11.6.7 Colombia

11.6.7.1 Colombia CNC Tool & Cutter Grinding Machine Market By Type

11.6.7.2 Colombia CNC Tool & Cutter Grinding Machine Market By Application

11.6.8 Rest of Latin America

11.6.8.1 Rest of Latin America CNC Tool & Cutter Grinding Machine Market By Type

11.6.8.2 Rest of Latin America CNC Tool & Cutter Grinding Machine Market By Application

12. Company Profiles

12.1 Vollmer

12.1.1 Company Overview

12.1.2 Financial

12.1.3 Products/ Services Offered

12.1.4 SWOT Analysis

12.1.5 The SNS View

12.2 Makino Milling Machine Co., Ltd.

12.2.1 Company Overview

12.2.2 Financial

12.2.3 Products/ Services Offered

12.2.4 SWOT Analysis

12.2.5 The SNS View

12.3 Haas Automation, Inc.

12.3.1 Company Overview

12.3.2 Financial

12.3.3 Products/ Services Offered

12.3.4 SWOT Analysis

12.3.5 The SNS View

12.4 ANCA Pty Ltd.

12.4.1 Company Overview

12.4.2 Financial

12.4.3 Products/ Services Offered

12.4.4 SWOT Analysis

12.4.5 The SNS View

12.5 ISOG Technology GmbH

12.5.1 Company Overview

12.5.2 Financial

12.5.3 Products/ Services Offered

12.5.4 SWOT Analysis

12.5.5 The SNS View

12.6 JTEKT Corp

12.6.1 Company Overview

12.6.2 Financial

12.6.3 Products/ Services Offered

12.6.4 SWOT Analysis

12.6.5 The SNS View

12.7 Korber AG

12.7.1 Company Overview

12.7.2 Financial

12.7.3 Products/ Services Offered

12.7.4 SWOT Analysis

12.7.5 The SNS View

12.8 Amada Machine Tools Co., Ltd.

12.8.1 Company Overview

12.8.2 Financial

12.8.3 Products/ Services Offered

12.8.4 SWOT Analysis

12.8.5 The SNS View

12.9 DANOBAT Group

12.9.1 Company Overview

12.9.2 Financial

12.9.3 Products/ Services Offered

12.9.4 SWOT Analysis

12.9.5 The SNS View

12.10 WIDMA Machine Tools

12.10.1 Company Overview

12.10.2 Financial

12.10.3 Products/ Services Offered

12.10.4 SWOT Analysis

12.10.5 The SNS View

13. Competitive Landscape

13.1 Competitive Benchmarking

13.2 Market Share Analysis

13.3 Recent Developments

13.3.1 Industry News

13.3.2 Company News

13.3.3 Mergers & Acquisitions

14. USE Cases and Best Practices

15. Conclusion

An accurate research report requires proper strategizing as well as implementation. There are multiple factors involved in the completion of good and accurate research report and selecting the best methodology to compete the research is the toughest part. Since the research reports we provide play a crucial role in any company’s decision-making process, therefore we at SNS Insider always believe that we should choose the best method which gives us results closer to reality. This allows us to reach at a stage wherein we can provide our clients best and accurate investment to output ratio.

Each report that we prepare takes a timeframe of 350-400 business hours for production. Starting from the selection of titles through a couple of in-depth brain storming session to the final QC process before uploading our titles on our website we dedicate around 350 working hours. The titles are selected based on their current market cap and the foreseen CAGR and growth.

The 5 steps process:

Step 1: Secondary Research:

Secondary Research or Desk Research is as the name suggests is a research process wherein, we collect data through the readily available information. In this process we use various paid and unpaid databases which our team has access to and gather data through the same. This includes examining of listed companies’ annual reports, Journals, SEC filling etc. Apart from this our team has access to various associations across the globe across different industries. Lastly, we have exchange relationships with various university as well as individual libraries.

Step 2: Primary Research

When we talk about primary research, it is a type of study in which the researchers collect relevant data samples directly, rather than relying on previously collected data. This type of research is focused on gaining content specific facts that can be sued to solve specific problems. Since the collected data is fresh and first hand therefore it makes the study more accurate and genuine.

We at SNS Insider have divided Primary Research into 2 parts.

Part 1 wherein we interview the KOLs of major players as well as the upcoming ones across various geographic regions. This allows us to have their view over the market scenario and acts as an important tool to come closer to the accurate market numbers. As many as 45 paid and unpaid primary interviews are taken from both the demand and supply side of the industry to make sure we land at an accurate judgement and analysis of the market.

This step involves the triangulation of data wherein our team analyses the interview transcripts, online survey responses and observation of on filed participants. The below mentioned chart should give a better understanding of the part 1 of the primary interview.

Part 2: In this part of primary research the data collected via secondary research and the part 1 of the primary research is validated with the interviews from individual consultants and subject matter experts.

Consultants are those set of people who have at least 12 years of experience and expertise within the industry whereas Subject Matter Experts are those with at least 15 years of experience behind their back within the same space. The data with the help of two main processes i.e., FGDs (Focused Group Discussions) and IDs (Individual Discussions). This gives us a 3rd party nonbiased primary view of the market scenario making it a more dependable one while collation of the data pointers.

Step 3: Data Bank Validation

Once all the information is collected via primary and secondary sources, we run that information for data validation. At our intelligence centre our research heads track a lot of information related to the market which includes the quarterly reports, the daily stock prices, and other relevant information. Our data bank server gets updated every fortnight and that is how the information which we collected using our primary and secondary information is revalidated in real time.

Step 4: QA/QC Process

After all the data collection and validation our team does a final level of quality check and quality assurance to get rid of any unwanted or undesired mistakes. This might include but not limited to getting rid of the any typos, duplication of numbers or missing of any important information. The people involved in this process include technical content writers, research heads and graphics people. Once this process is completed the title gets uploader on our platform for our clients to read it.

Step 5: Final QC/QA Process:

This is the last process and comes when the client has ordered the study. In this process a final QA/QC is done before the study is emailed to the client. Since we believe in giving our clients a good experience of our research studies, therefore, to make sure that we do not lack at our end in any way humanly possible we do a final round of quality check and then dispatch the study to the client.

The Air conditioning System Market size was valued at USD 126.02 Bn in 2023 and is expected to reach USD 215 Bn by 2031 and grow at a CAGR of 6.87 % over the forecast period 2024-2031.

The Smart Elevator Market size was estimated at USD 26.564 billion in 2022 and is expected to reach USD 53.712 billion by 2030 at a CAGR of 9.2% during the forecast period of 2023-2030.

The Stone Crushing Equipment Market Size was valued at USD 5.70 billion in 2022 and is estimated to reach USD 10.80 billion by 2030 with a growing CAGR of 8.3% over the forecast period 2023-2030.

The Oil and Gas Accumulators Market Size was esteemed at USD 564.67 million in 2022 and is supposed to arrive at USD 831.10 million by 2030 and develop at a CAGR of 4.95% over the forecast period 2023-2030.

The Fuel Transfer Pumps Market size was valued at USD 1.82 Bn in 2023 and is expected to reach USD 2.60 Bn by 2031 and grow at a CAGR of 4.65 % over the forecast period 2024-2031.

The Automatic Labeling Machine Market size was estimated at USD 2.6 billion in 2022 and is expected to reach USD 3.47 billion by 2030 at a CAGR of 3.7% during the forecast period of 2023-2030.

Hi! Click one of our member below to chat on Phone